Ice Packaging 101: Types, Benefits, and Best Practices Explained

July 04, 2025

Want to prevent spoilage and extend the shelf life of your perishable goods like seafood, meat, or dairy products? What solution comes to your mind? To answer this, there is no other than ice packaging maintaining temperatures to preserve the freshness and quality of your perishable products.

From ice packs and dry ice to insulated containers, efficient ice packaging reducing waste, and enhancing customer satisfaction ensures that perishable items arrive in pristine condition.

Stick to this blog to learn how this ice packaging is good for various industries including medical, food, and beverages to keep your perishable goods cold and retain their quality for longer.

We will also learn types of ice packaging with its benefits and effective practices for the success of a business.

What is Ice Packaging

Chill out with premium ice packaging that refers to the packaging materials and methods to store and transport ice. The ice remains frozen and intact during distribution.

Insulated containers, ice plastic bags, and ice blocks are included in this packaging. These ice packaging packs are designed to minimize heat transfer and prevent ice from melting.

Serving industries from seafood and medical to food and beverages, this packaging is perfect to keep products cold. Further, it protects ice and maintains the temperature of the items inside that it intends.

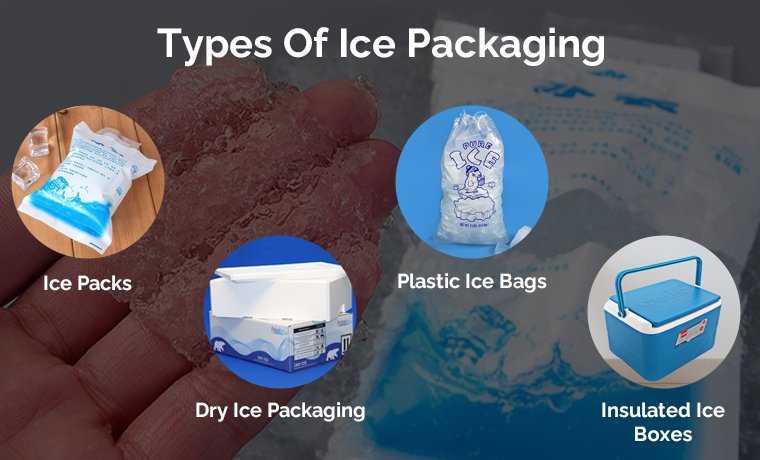

Types Of Ice Packaging

There are many types of ice packaging found to keep perishable products cold during storage and transit. Each ice packaging type serves different purposes. They are chosen based on the product needs that are being transported. Here they are.

Ice Packs

These are reusable gel or water-filled packs that are used to maintain the temperature of the products.

Dry Ice Packaging

A solid form of carbon dioxide (CO₂) that sublimates at -78.5°C (-109.3°F) to keep perishable items cold.

Ice Block Packaging

These are large ice blocks that maintain temperature during storage and transit. They are found in seafood and perishable goods shipping. For transporting biological samples, pharmaceuticals, food, and beverages, this ice block packaging is ideal.

Plastic Ice Bags

These ice bags are biodegradable and filled with ice. They are used in food and catering services. Meeting FDA & USDA requirements for food contact these ice bags size ranges from 5lb, 8lb, 10lb, 20lb, and 50lb.

Foam Coolers

They are lightweight and portable styrofoam coolers made from foam insulation to keep perishable products cold during transportation.

Insulated Ice Boxes

These insulated boxes are containers made from materials like Styrofoam that provide thermal insulation for ice and perishable items.

Ice Bricks

Strong and rigid containers filled with water or gel that freeze solid provide long-lasting cold retention. These BPA-free and reusable ice bricks are leakproof.

They are found in a slim design. The most common size of an ice brick is 32cm x 1.25cm x 25.5cm. They keep food and drinks fresh and cold.

Thermal Liners

These reflective liners are insulating materials and are used within shipping boxes to enhance temperature control. They prevent heat transfer to keep perishable goods cold and provide extreme thermal protection from heat.

Benefits Of Ice Packaging

Ice packaging is essential to keep perishable products fresh and maintain their integrity ensuring their safety and enhancing overall customer experience.

You can enjoy many perks of ice packaging while presenting, storing, and transporting perishable goods like seafood and meat.

Preservation Of Freshness and Quality

Ice packaging preserves the freshness and quality of perishable products by maintaining a low temperature during transit.

Food Safety and Security

Properly made ice packaging helps to prevent bacterial growth and reduce the risk of foodborne sickness.

Extended Shelf Life Of Perishable Products

Ice packaging prolongs the shelf life of perishable items which require a longer shipping time.

Temperature Control

Ice packaging ensures that perishable items are at optimal temperatures.

Customer Satisfaction

Products remain safe in ice packaging and arrive in excellent condition which satisfies customers. It enhances the overall experience and builds the trust of a brand over its customers.

Brand Recognition

Premium quality ice packaging reflects the true identity of a brand and shows its commitment to quality and customer care.

Best Practices For Effective Ice Packaging

Here are the best practices for ice packaging to help you achieve your goals. Implementing these effective practices can help you retain the quality and safety of your perishable products during transit while ensuring customer satisfaction.

Choosing the Right Ice Packaging Type

Making the right selection of ice packaging depends upon the products, distance of transportation, and temperature. You can choose ice packs, dry ice or insulated containers for your products.

Using High-Quality Insulation

Be sure the ice packaging you are using has high-quality insulation to minimize temperature fluctuations. Styrofoam or thermal liners can help you maintain cold temperatures for longer.

Pre-Chill Packaging Materials

Before packing, pre-chill ice packs, containers, or other items that directly come into contact with the product to maximize cooling efficiency.

Seal Your Ice Packaging Tightly

Make sure the ice packaging is sealed properly to prevent air exchange that can lead to melting temperature loss.

Proper and Clear Labeling

Use clear labels on ice packaging that include handling instructions and essential information indicating that the package contains perishable items.

Minimize Exposure To Heat

Avoid exposing ice packaging to direct sunlight during loading and unloading.

Going Green

Choose sustainable packaging materials for ice packaging to reduce environmental impact.

Understanding Ice Pop Packaging

Ice pop packaging is a packaging material and design that is used to contain and protect ice pops, and frozen treats made from flavored liquids. It protects perishable products and maintains their freshness. Besides this, it brings convenience to customers.

How To Dispose Of Dry Ice Packaging

Disposing of dry ice packaging safely and securely is essential to prevent hazards. Here are some guidelines: Following these steps ensures safe disposal!

- Allow Sublimation: Let dry ice sublimate in a well-ventilated area until it completely turns to gas from liquid.

- Avoid Sealing: Dry ice should not be sealed in airtight containers

- Wear Gloves: Wear gloves when handling dry ice to avoid frostbite.

- Check Local Regulations: Check the local disposal guidelines.

- Recycle Packaging: Keep any packaging that does not contain dry ice, such as Styrofoam, and recycle it.

In A Nutshell

Effective ice packaging in a growing and competitive market is more than a logistical necessity. This packaging is ideal for keeping seafood quality and integrity while satisfying customers. Companies looking for a safe transportation solution for their perishable goods can invest in ice packaging to embrace sustainable practices that are better for both the consumer and the business.

For assistance regarding custom packaging for your perishable goods, you are welcome to partner with Custom Product Packaging. We are here to answer your queries. Don’t hesitate to drop us an email at orders@customproductpackaging.com. Our professionals are here for your help.