Paper Tube Manufacturing: Everything You Need to Know

September 04, 2025

Saying packaging brings a picture of a box or bags to our minds. Customers are already aware of these custom packaging solutions. That’s where the opportunity comes for an emerging business. You can grab this lucky chance by thinking out of the box and leaving traditional packaging behind. Guess what it is? You are probably unaware of paper tubes with enough strength to provide versatile packaging and sustainable solutions.

This guide will teach you how paper tubes are produced, their types, and what industries they serve. You will learn how they help reduce carbon footprints while presenting, storing, and protecting your products. Without wasting time, let’s explore its uses and benefits.

What Are Paper Tubes

Paper tubes - cylindrical structures made from layers of paperboard or cardboard wound and glued together. They are an excellent choice for various industries for safe product delivery. These lightweight paper cores and tubes are constructed with recycled paperboard. This makes them easy to transport and customize with your logo and colors.

They are used in packaging, automobile, textile, art supplies, and food industries. Every industry has its own need for a specific thickness. That’s why these paper tubes can be classified by tube length, diameter, and thickness.

When Paper Tubes Were Created For The First Time

Kai Lun, from China, was the first man to revolutionize the paper-making process in 105 AD. He invented paper using trees, cloth pulp, hemp ends, and fishing nets, transforming it into large-scale, low-cost paper manufacturing. The use of paper kept spreading throughout the world over centuries. It was in the 1600s when the first cardboard was invented and introduced from China.

Invention Of Paper Tubes That We Use Today

In the mid-1800s, paper tubes were invented using a grinding machine. Paper production became more efficient and cost-effective over time.

1843 - The Beginning

In 1843, the machine was used in Germany. This was used to transform wood into pulp, making it easier to create paper. This innovation gave birth to cardboard and paper tubes, and later on, their production started.

1900s - Innovations

In the 1900s, paper tubes were used in many industries, such as textile and packaging. Due to its versatility, lightweight, and recyclability features, these paper tubes were adopted by many industries. Even they were used as cores for adhesive tapes.

Today, paper tube packaging is still the first choice of many industries when it comes to packing and storing items.

How Paper Tubes Manufacturing Process Goes?

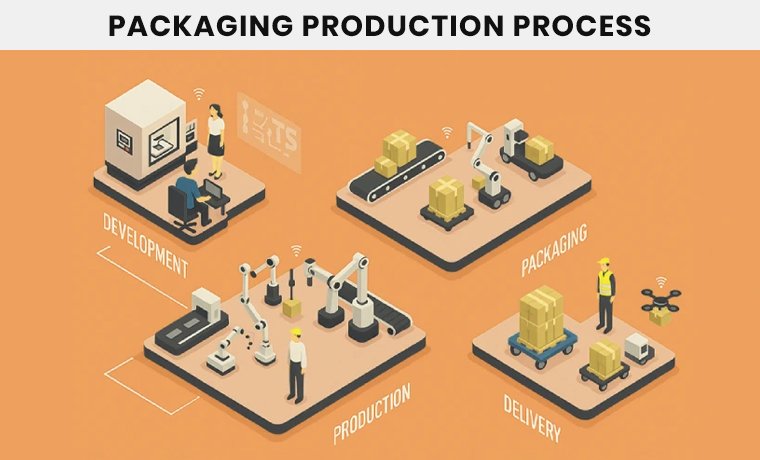

The production process of manufacturing paper tubes involves several steps combining the material selection offering durability to create a cylindrical structure.

Materials Required to Produce Paper Tubes

Wood pulp materials in the form of recycled paper are:

- Cardboard

- Kraft

The outer layers of paper tubes are made from the most strong, durable, and sustainable materials.

Manufacturing Process

- First, the larger paper sheet is cut into thin strips.

- An adhesive coating is applied to the strips for wrapping.

- The recycled paper with adhesive coating is wrapped around the mandrel. This mandrel helps you determine the inner diameter of paper tubes.

- Then these tubes are passed through heated tunnels or air drying.

- Certain dry time is required after the layers are wrapped around the mandrel.

- Paper tubes are formed now. Ready to cut into the desired length.

Types of Paper Tubes by Application

Paper tubes can also be classified by their purpose. They are specifically designed to help flawlessly carry out the application.

1. Kraft tubes

Made of high-quality kraft paper is a durable and versatile cylindrical kraft tube. It offers high strength and resilience to withstand pressure and protect enclosed items. They are used as postal tubes. Ideal for mailing posters, blueprints, artwork, and other rolled documents.

2. Shipping tubes

Shipping tubes are specially designed in kraft brown or white for the safe transport of long, rolled, or elongated items. You can find them in various sizes and thicknesses. Heavier-duty shipping tubes may use thicker corrugated fiberboard. Most often its shape is round. It is perfect for protecting the packed items by absorbing the transit shocks from denting and tearing.

3. Paper Cores

Paper cores made from paperboard-wound plies. They provide stability for winding and storing materials such as fabric, electrical, paper, and textile. Offering sturdiness and eco-friendly solutions, suitable to serve a variety of purposes in various industries.

4. Sonotubes

Sonotubes are heavy-duty cardboard tubes and are treated with a wax coating or laminate to make them water-resistant. Contractors use these heavy-duty paper tubes in various property construction processes. The purpose is to form concrete pillars, light poles, decks, stub piers, and support columns for buildings for elevated ramps.

5. Caulking tubes

Caulking tubes also known as spiral wound paper tubes are used to dispense caulk or other sealants in construction. Traditionally, they are made from cardboard with an inner lining to prevent the caulk from adhering to the tube. Typically, they are used with a caulking gun to apply pressure to the tube and force the caulk out through the nozzle.

6. Paper cans

Paper cans are made primarily from paper or cardboard. They're used for a variety of packaging and storage purposes. A popular choice in terms of protection during transit and eco-friendly nature. Most commonly these cans are used for packaging dry goods like tea, coffee, spices, and snacks.

Key Benefits of Paper Tubes for Sustainable Packaging

Paper tubes offering endless customizations and sustainability can help reduce carbon footprints. Its pros are:

- Paper tubes made from recycled materials contribute to reducing footprints.

- A good choice due to their versatility, strength, and sustainability.

- Easy to recycle and reuse.

Pros of Paper Tubes in Customizations

- Customizable in different sizes, lengths, and thicknesses.

- Durable and flexible yet strong enough to handle customization preferences.

- The lightweight feature of paper tubes reduces shipping costs and makes convenient portability.

- Offers protection against moisture when they are designed with waterproof coatings.

- Cheaper than glass, metal, plastic, or wood.

- Easy to cut and use.

- Can be used with various exclusive finishing and printing options.

Wrap Up All The Things

Paper tubes have revolutionized the history of the packaging industry. It has gained popularity due to its efficiency, cost-effectiveness, and eco-friendly features. If you seek to package paper tubes and want to learn more about how paper tubes are transforming the packaging industry, look no further than Custom Product Packaging. We specialize in producing paper tubes in various colors using the highest-quality materials. Reach out to us by email at orders@customproductpackaging.com.Our online form is available for your convenience. You can fill it out and send your requirements.