What Are Blister Packs For Medication and Pharmacy?

September 08, 2025

When it comes to drugs and medications, it is not just about packing them; maintaining their quality and protection is the top priority.

The packaging in this context is equally important as the medication. That’s where blister packaging comes in for:

- Protecting the integrity of the medicine

- Ensuring accurate dosage

- Preventing contamination or tampering

Blister packaging plays a critical role in the pharmaceutical industry. It not only secures the medication but also enhances shelf life, patient safety, and ease of use.

- Blister packs improve medication adherence by 15-30% (WHO).

- PVC blisters dominate 60% of the pharma packaging market (Grand View Research).

Whether you are a new startup or an established pharmaceutical company, understanding blister packaging, its types, benefits, and the materials needed is essential.

What is The Purpose of Blister Packaging?

Blister packaging is one of the four types of packaging that prevent tampering with medicines. It is widely used for packaging:

- Pills

- Tablets

- Capsules

- Other solid-dose medications

The blister packs consist of a thermoformed plastic cavity that holds individual doses, securely sealed with a backing material like aluminum foil.

The primary purposes of blister packs include:

- Protection of medicines from moisture, oxygen, and light

- Tamper evidence to ensure product safety

- Dose accuracy by isolating individual units

- Patient compliance through easy tracking of medication intake

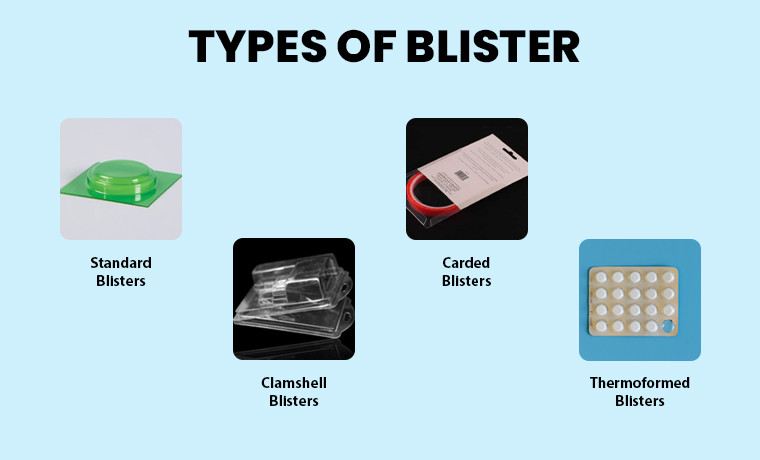

Four Different Types of Blister Packaging

The top four types of blister packaging are here.

1. Standard Blisters

The most common type of blister pack is with a molded plastic front and a seal at the back.

2. Carded Blisters

A clear blister pack combined with a printed info card carrying branding, instructions, and other details offers balanced product protection, brand visibility, and convenience.

3. Clamshell Blisters

The transparent blister card packaging is folded to create a secure plastic shell, enhancing product visibility while minimizing contact risk.

4. Thermoformed Blisters

Made by molding plastic using heat, this process shapes plastic sheets into individual blisters to hold medicines, effectively displaying and protecting them.

What are the Best Materials Used in Manufacturing Blister Packs?

Why do drug companies use blister packs? Here are the materials.

1. PVC (Polyvinyl Chloride)

Cheaper and easier to thermoform. Less effective against moisture and oxygen due to its poor barrier properties.

2. PVDC (Polyvinylidene Chloride)

Coated blister films onto PVC with moisture and oxygen barrier properties are an economical option.

3. PCTFE (Polychlorotrifluoroethylene)

Known for its exceptional barrier properties, it is highly resistant to moisture and oxygen when laminated to PVC.

4. COC (Cyclic Olefin Copolymers)

Made with a blend of high-barrier properties to protect sensitive pharmaceuticals and medicines.

Read More: 2025 Packaging Design Software Guide (Pro Insights and Tips)

6 Key Benefits of Blister Packaging

There are many reasons pharmacies use blister packs for medications. Let’s list them.

1. Convenience

The user-friendly design allows patients to dispense each dose as needed easily.

2. Protection

Each pill or capsule packaged in blister packaging is properly sealed and protected from environmental exposure, such as moisture and air, that could degrade the drug’s efficiency.

3. Tamper-Proof Design

Blister packs are specially designed with enhanced safety to make it evident if the pack has been tampered with.

4. Easy To Carry

The slim and lightweight packaging designs of blister packs for medication make them ideal for patients and help them carry medicines comfortably.

5. Visibility

The transparent plastic blister packs allow patients to view the medicines without opening them.

6. Medicine Information Display

Provides essential information about the medicines and dosage instructions, including the medicine name and the manufacturing company.

Do Pharmacies Still Use Blister Packs?

The simple answer is “YES”. Pharmacies still prefer blister packs for medications because they offer a convenient and organized way to manage prescriptions.

They are especially useful for patients who take multiple medications or have difficulty remembering their daily doses. Blister packs continue to be widely used to meet individual patient needs.

Top Blister Packaging Examples

Here are some examples of products packaged in blister packs.

| Sectors | Products |

| Electronics | USB drives, batteries, earphones, memory cards |

| Toys | Action figures, small toys, bobbleheads |

| Stationery | Pens, markers, paper clips, glue, drawing pins |

| Medications | Tablets, capsules, and other pharmaceutical products |

| Hardware | Screws, nails, bolts, and small tools |

| Toothbrushes | A single toothbrush is often packaged in blister packs |

Where to Buy Blister Packs for Medication?

Blister packs can be purchased online or from physical stores.

Community Pharmacies

Many local pharmacies offer blister packaging services, especially for those who take multiple medications.

Online Pharmacies

Amazon Pharmacy offers blister packs through the PillPack service.

Online Retailers

Amazon and Walmart sell various types of blister packs and refill cards.

Pillcards.com

Pillcards.com offers multiple-dose medication blister cards.

Concluding Thoughts

The pharmaceutical industry faces many challenges from rising costs and strict compliance regulations to marketing demands and limited storage space. In this case, understanding blister packaging, its types, materials, and benefits can help pharmaceutical companies address all the concerns effectively and stay competitive by offering protective, tamper-evident, and patient-friendly solutions.

To learn more about pharma packaging boxes, one must approach Custom Product Packaging to experience the best packaging solutions at affordable rates. Email us at orders@customproductpackaging.com.