How Does the Packaging Production Process Work?

January 30, 2026

Packaging material is the mirror reflection of the product inside it.

The initial physical touch that a customer receives with any given product is the packaging. The packaging production actually has a direct influence on purchase decisions. With a properly organized manufacturing and packaging cycle, the product is secured, the brand is always the same, and the distribution becomes cost-efficient.

Premium rigid stock boxes, certified food-safe cartons, and other current processing packaging techniques are the results of engineering accuracy and artistic design. The brands that know this workflow can reduce the risks of damage and manage the material prices.

What is Packaging Production?

The process of changing raw materials into functional and branded packaging solutions is coordinated and referred to as packaging production. It combines:

- Material engineering

- Structure design

- Printing technology

- Automated assembly

The goals are to attain product safety, good shelf position, and long-term performance. Moreover, premium products are often shipped or displayed in rigid stock packaging because of their high strength and premium look.

A Quick Overview Of Packaging Materials:

| Packaging Type | Material Base | Strength Range | Core Benefit | Typical Use |

| Rigid Box Production | Greyboard + Art Paper | 800–1800 GSM | Premium strength and appeal | Luxury retail |

| Folding Carton Production | Paperboard | 250–450 GSM | Lightweight and printable | Consumer goods |

| Corrugated Box Manufacturing | Kraft + Fluted Core | A - F Flute | Shipping protection | eCommerce |

| Flexible Packaging Production | Plastic + Foil Films | 50–200 Microns | Airtight Sealing | Food Items |

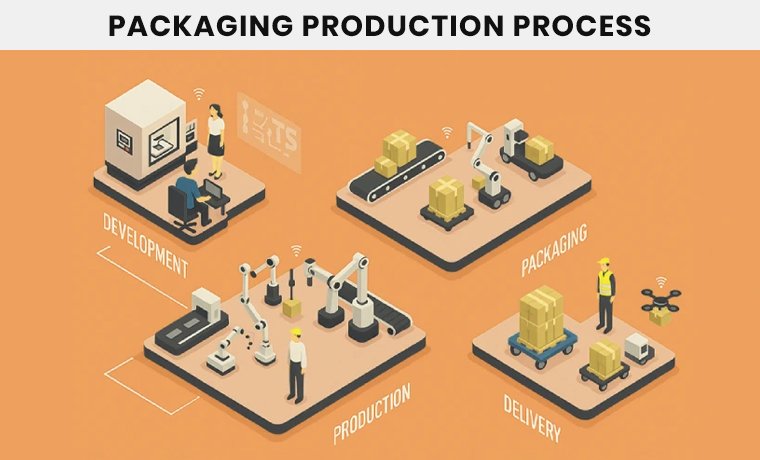

Packaging Production Process in Stages

1. Requirement Analysis

The process of production starts with the provision of both functional and technical packaging requirements. Engineers consider the features of the product and branding goals before initiating. Also, they can suggest which model will work best with their product.

This action will make sure that packaging performance is in line with handling conditions, storage conditions, and expectations of the target market.

Must Consider:

- Size, fragility, and weight of the product.

- Budget of the customer

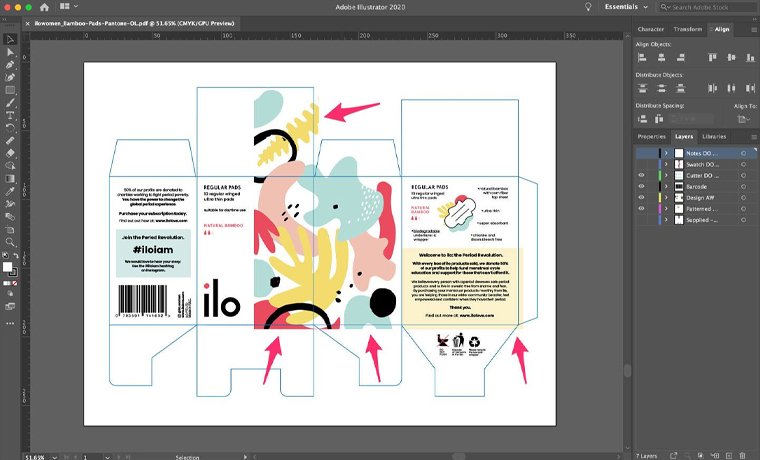

2. Structural Design and Prototyping

Structural design then changes the concept into box formats that can be produced after the requirement definition. Dielines, fold structures, and glue layouts are created with high-dimensional accuracy with the use of CAD software.

Prototypes are made, and then they are tested on fit, opening experience, and efficiency of assembly. This confirms that the design is feasible when mass packaging will get started.

3. Stock Selection

The packaging has its durability, appearance, and sustainability determined by the choice of material. Most importantly, the type and coating of boards are differentiated according to the weight of the product, contact with the environment, and branding requirements.

Remember, luxury packaging production is still done using rigid stock because of its high finishability and rigidity.

- Cardboard Stock: Made from single-layered paperboard with a common thickness range of 250-450 GSM.

- Kraft Stock: Produced from wood pulp fibers with an organic brown appearance.

- Rigid Stock: Manufactured with compressed greyboard sheets - thickness ranges from 800 to 1800 GSM.

- Corrugated Stock: Made from fluted paper with a lining inside and available in A, B, C, D, E, and F flute types.

- Holographic Card Stock: Contains reflective film layers with dynamic color-shifting capabilities.

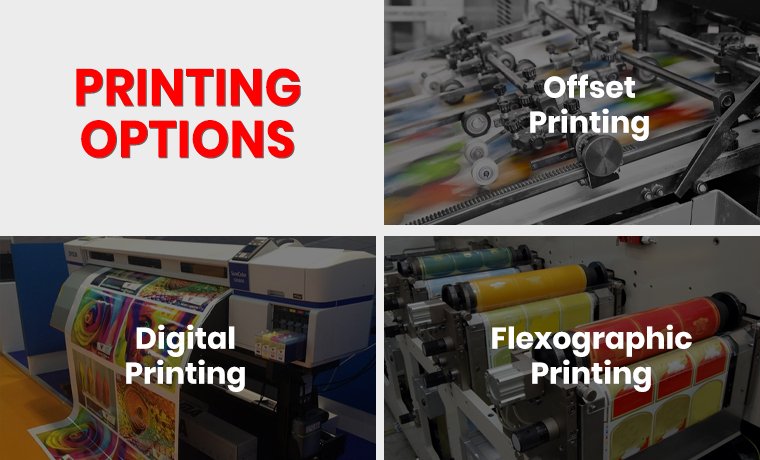

4. Printing Options:

Printing makes packaging attractive for the buyer with its color accuracy. Further, the alternative printing methods used are picked per the type of materials and the company's demand. A few of the worth mentioning and most commonly used printing options are :

- Offset Printing

- Digital Printing

- Flexographic Printing

Bonus: The production processes of food packaging materials prioritize certified inks and safe coatings.

5. Finishing & Add-ons

Finishing increases the packaging strength, appearance, and experience. Be it lamination, coating, or finishing, each is considered to add value to the brand and consumer interaction. Similarly, you can go for embellishments or functional add-ons as the customer demands:

- Lamination for protection

- Spot UV highlighting

- Foil stamping in any color (copper, gold, silver, and holographic)

- Embossed textures

- Magnetic closures

- Ribbon pull features

- Product display windows

- Bespoke interior inserts

6. Quality Control & Testing

The quality control is necessary for the reliability of packaging and the good reputation of the brand.

- Strength test determines the compression value, load capacity, and impact strength.

- Moreover, checking of products under conditions of shipment is referred to as drop testing.

- Print checking is used to check the consistency of color, alignment, and adhesion of the coating.

7. Preparation of Packing & Distribution

After passing through inspection, final assembly starts!

Custom boxes are either shipped completely assembled or flat according to the client's needs and the box’s structure. The bulk is packed effectively in folding cartons to conserve shipping space, ultimately cutting down expenses. This final stage connects packaging production with supply chain performance, helping businesses maintain production schedules and meet market standards.

Conclusion

Production of packaging is done with high-technical accuracy, knowledge of materials, and creative branding to provide the result that protects and sells. Every single process, design, and test adds up to performance, sustainability, and the vibe of the box. Advantages in modern manufacturing and packaging have resulted in higher output with less waste and shorter turnaround times for the brands.

Do you like to have an end to end custom printed packaging that actually resonates with your brand palette, supports its ethos, and promotes product recall? Get your "designed to sell" boxes with your logo and personalized artwork from Contact Custom Product Packaging. From the lowest MOQs and 3D mockups to free design assistance and free shipping, we are your “well-wisher” in high-quality packaging production. Ring us at (+1) 888-511-592 or shoot an email to orders@customproductpackaging.com.