What is Tertiary Packaging and How is it Used?

December 16, 2025

How do you take packaging for your products? If you are considering packaging just for protection, it's just a limited thought. Leave it aside.

In this modern age, packaging is not just to house the product. It can be a powerful marketing tool and build brand identity while keeping your products safe.

When we look into packaging, three levels emerge:

- Primary —-- holds the product (e.g., bottles)

- Secondary —-- groups multiple primary packages for handling (e.g., boxes)

- Tertiary —-- used for bulk transport and storage (e.g., pallets)

Bottles as primary packaging and boxes as secondary packaging are very common. However, you may not be well aware of tertiary packaging. Worry not!

This blog will discuss tertiary packaging and its types. You will learn its examples, pros, and cons to meet your packaging needs.

What Actually is Tertiary Packaging?

The tertiary packaging definition in short is an additional layer of packaging to group, protect, and transport large quantities of products. It is designed to keep bulk products secure from external damaging factors. For handling, storage, and shipment of large amounts of goods, this packaging is ideal.

8 Most Common Examples of Tertiary Packaging

The key tertiary packaging examples are here.

- Pallets: They stack and transport goods.

- Shrink and Stretch Wrap: To wrap and secure grouped products or pallets for easy handling and transport.

- Corrugated Boxes: To consolidate smaller packages.

- Crates: Durable containers for shipping heavy or bulky items.

- Shipping Containers: Standardized steel containers for international freight.

- Strapping Bands: Plastic or metal bands used to secure items on pallets.

- Protective Foam & Cushions: Used for absorbing sudden shocks and preventing damage.

- Rigid Containers: For transporting sensitive or high-value items.

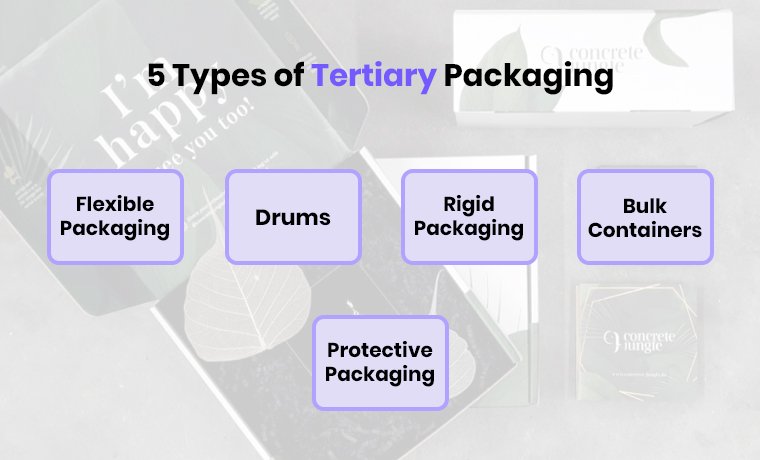

5 Types of Tertiary Packaging

There are different types of tertiary packaging in the market. The four most common types are here.

1. Flexible Packaging

Contains stretchable films and shrink wraps. It is used for packing lightweight items.

2. Drums

Cylindrical containers are used for shipping bulk liquids or powders.

3. Rigid Packaging

Wooden crates, metal drums, and hard plastic containers come under this packaging level. For protecting and storing heavy goods, this type of packaging is used.

4. Bulk Containers

Consists of large sacks and barrels. They are used for liquid and granulated products.

5. Protective Packaging

It includes foam inserts and air cushions. Ideal for shielding delicate and fragile items.

Material Used for Tertiary Packaging

The most common materials used in tertiary packaging are.

- Corrugated cardboard (e.g. trays or boxes)

- Plastic (e.g. tanks or big bags)

- Wood (e.g. Euro pallets or crates)

- Metal (e.g. mesh boxes or barrels)

- Film (e.g. shrink or stretch films)

The weight, height, and nature of the products can help you decide which material you should choose. Carefully select the suitable material for your product.

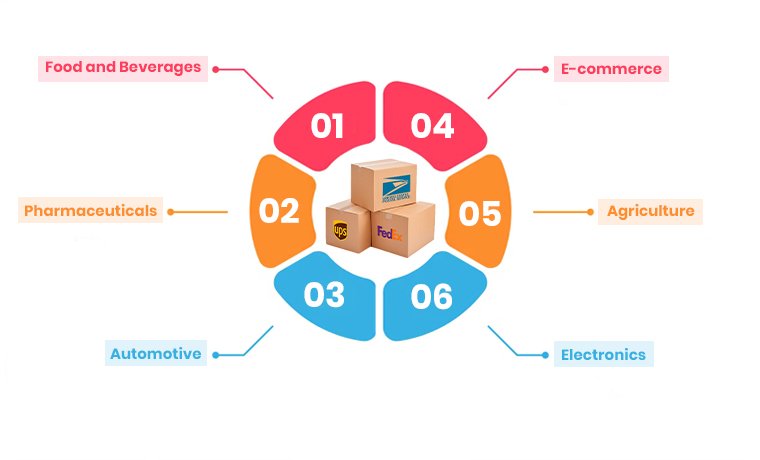

Application of Tertiary Packaging in Various Industries

Tertiary packaging is used in various industries. The purpose is to efficiently handle, store, and transport bulk goods.

-

Food and Beverages

The food and beverage industry uses pallets, crates, and shrink wrap. Their uses are common to secure cartons of canned or bottled drinks.

-

Pharmaceuticals

Pallets and folding cardboard cartons ensure the safe shipment of medicines in bulk.

-

Automotive

Bulk containers, pallets, and crates are widely used to ship auto parts and components in big quantities.

-

E-commerce

Many online businesses use tertiary packaging to ship their products to customers. For instance, potato chips are packed in a folding carton. And then placed on pallets and shipped to customers.

-

Agriculture

Wooden crates, pallets, and bulk bins are used to ship bulk agricultural products such as grains or vegetables.

-

Electronics

Pallets, Gaylord boxes, stretch, and shrink wraps help transport units of electronic items safely.

Pros and Cons of Tertiary Packaging

Tertiary packaging has both advantages and disadvantages. Have a look at them below.

Advantages:

- Minimizes the breakage of products during transit.

- Easy to stack and transport products.

- Packing products in bulk eliminates the need for secondary packaging. This reduces the costs.

- Compatible with warehouse automation systems.

- Many types of tertiary packaging materials are recyclable.

Disadvantages:

- Extra materials such as pallets and stretch wraps are required.

- You need a massive warehouse space to store products in bulk.

- Not all tertiary packaging materials are eco-friendly.

- Raises the cost of packaging and transportation.

Also Read: Main Types of Retail Packaging With Pros and Cons: Which Is Right To Boost Your Brand

Interaction of Tertiary Packaging with Primary and Secondary Packaging

Here is a brief comparison of primary, secondary, and tertiary packaging for your understanding.

| Packaging | Function | Purpose | Examples |

| Primary Packaging | Provides the first layer of defense to protect the product | Directly holds and contains products | Bottles, cans, tubes, blister packs |

| Secondary Packaging | Adds more protection to facilitate handling and branding | Groups multiple primary packages together | Cardboard boxes, cartons |

| Tertiary Packaging | Consolidates secondary packages for smooth transportation | Bulk storage and transporting | Pallets, crates, large containers |

Conclusion

Tertiary packaging plays a significant role in the supply chain for the safe storage and transportation of products. This packaging offers extreme protection and support during storage and transit. Not just that. Also, it improves logistics and reduces damage. This helps in facilitating the handling and distribution of bulk goods.

Stop looking here and there. Custom Product Packaging manufactures superb quality tertiary packaging. Whether you need folding cartons or corrugated boxes, contact us. All you need to do is just email us at orders@customproductpackaging.com. We will promptly respond to address your concern.