Corrugated Fiberboard: Everything You Need to Know

September 05, 2025

A safe delivery begins with the right packaging when shipping something important. It is because damaged goods cost more than just money. Whether it is a customer order, a gift, or a fragile item, packaging matters.

Have you ever opened a box only to find your item broken or crushed? Nobody likes to receive products in a damaged state. That’s often due to poor packaging choices.

That’s where corrugated fiberboard comes in.

- Sturdier

- Lightweight

- Built to withstand the rigors of shipping

It is the go-to solution for anyone serious about protecting their products during shipping.

This blog will guide you through everything you need to know about corrugated fiberboard— how it is made, why it works, and how it can benefit your packaging strategy.

What is Corrugated Fiberboard?

Corrugated fiberboard, also known as corrugated cardboard, is a versatile packaging material made from fluted (wavy) layers sandwiched between flat linerboards. This forms a sturdy structure. It provides strength, durability, lightness, and protection.

It is Perfect for Shipping cartons, Retail packaging, and product displays. You can easily customize it into various sizes and shapes to make:

- Boxes

- Folding cartons

- Protective packaging

According to FEFCO, over 90% of shipped goods in Europe are packed in corrugated fiberboard. Corrugated packaging has a 92% recycling rate — the highest of any packaging material.” – Source: EPA

History and Invention Of Corrugated Fiberboard

The idea of creating corrugated fiberboard was inspired by architectural uses of curves to make them stronger. This logic was initially used to resist bending and pressure on corrugated boxes and became successful. Finally, corrugated cardboard came into being.

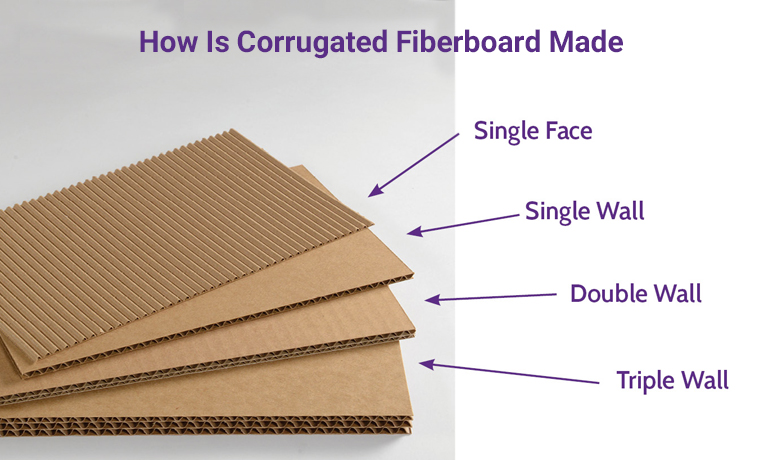

How is Corrugated Fiberboard Made?

Corrugated fiberboard gets its strength from a clever design: a wavy layer of paper (called fluting) is glued between flat sheets. These are called liners and flutes.

The standard structure includes inner and outer liners with the fluting sandwiched in between.

Need more protection? Just add layers. Corrugated boards can be made stronger by using a number of layers (two, three, or even five layers) to make the board stronger, based on how much protection the product needs.

Common Types of Corrugated Fiberboard

To give more strength to your corrugated box, you can add three or five flat sheets, combining two or three wavy layers. The more fluting you use, the stronger and more durable your box is.

1. Single face

A single piece of corrugated paperboard glued to a flat paperboard sheet.

2. Single-Wall

A single wavy corrugated paperboard layer is glued with two flat paperboard sheets in between.

3. Double-Wall

Two pieces of wavy corrugated paperboard are glued with three flat paperboard sheets in between.

4. Triple-Wall

Three layers of corrugated medium sandwiched between four outer liners for exceptional strength.

Which Corrugated Structure is Right for You? Check the Comparison Table

Refer to the table below to gain a better understanding of corrugated fiberboard.

| Features | Layers | Strength Level | Ideal for |

| Single-Face | 1 liner + 1 flute | Low | Lightweight products |

| Single-Face | 2 liners + 1 flute | Medium | General shipping |

| Double-Wall | 3 liners + 2 flute | High | Heavy electronics |

| Triple-Wall | 4 liners + 3 flute | Higher | Industrial goods |

Key Benefits Of Corrugated Fiberboard

There are many advantages of corrugated fiberboard in designing boxes for your products. Let’s break them down.

Lightweight

Easy to handle and transport, which reduces shipping costs.

Strength and Durability

Offers excellent protection to your products during transit with varying strength levels depending on the construction (single, double, or triple wall).

Customizability

Customizable in any size, shape, and design to meet packaging needs.

Cost-Effective

Economical and pocket-friendly option for businesses.

Recyclable

Made from renewable resources and can be recycled. A good eco-friendly choice.

Cushioning

The fluted structure protects fragile items from uncertain damage.

Branding

Printable with custom graphics and branding attributes to enhance product visibility while promoting a brand.

Versatility

Suitable packaging for a wide range of products.

Best Uses Of Corrugated Fiberboard

There is no limit to its uses due to its strength, lightweight nature, and versatility.

Retail Packaging

An excellent choice to create display boxes and product packaging with printed and branding features to showcase various products at retail stores.

Moving Boxes

When you shift or relocate, the moving boxes made out of corrugated fiberboard provide sturdier support for your household items.

Point-of-Purchase Displays

Display and promote your products to capture the attention of maximum customers at retail stores.

Protective Packaging

For cushioning your delicate and fragile items, such as glassware and electronics.

Shipping Boxes

Ideal for packaging and shipping goods while protecting them during handling and transit.

Food Packaging

A suitable option for takeout boxes and containers to resist moisture.

How To Make A Cardboard Box Using Corrugated Fiberboard?

So simple. It is easy to create a cardboard packaging box using corrugated packaging sheets.

Materials Needed:

- Corrugated fiberboard

- Ruler

- Pencil

- Box cutter

- Tape or glue

Instructions:

- Measure and Cut: Determine the box dimensions and cut a flat piece of fiberboard accordingly. (2, 3, or 4 flat paperboard sheets)

- Create Flaps: Mark and cut flaps on two opposite sides of the main panel.

- Score Fold Lines: Use a ruler to score where the box will fold for clean edges.

- Fold the Box: Fold up the sides and flaps along the scored lines.

- Assemble: Secure the flaps to the sides with glue.

- Seal the Bottom: Fold and tape the bottom flaps to complete the box.

- Optional Decoration: Add labels or decorations as desired.

Your sturdy packaging box is ready. Say WOW!

Sustainability of Corrugated Fiberboard

Corrugated fiberboard is considered the most recyclable packaging material as it is made from recycled material. So, it can be renewed multiple times. Its sustainability reduces waste and lowers environmental impact.

This is the reason many businesses favor this packaging material, providing not only enough power and resilience but also contributing to saving the planet.

How is Corrugated Fiberboard Customizable?

Investments in corrugated are expanding as the printing and packaging industry is evolving. Recognizing the interest of businesses in corrugated boxes, they can be designed and tailored to meet specific needs.

From the box dimensions to printing and finishing, there is a limitless sky allowing you to customize the box the way you want.

Sizes and Shapes

The boxes made with corrugated fiberboard is customizable in various sizes and shapes to accommodate different types of products. Provides complete safety during storage and transit.

Flute Size

The flute (flute A, flute B, and flute C) offers thickness and cushioning to your products. You can adjust it according to your requirements.

Design

Using eye-catching graphics, you can design corrugated boxes. Furthermore, you can add additional features such as handles and die-cut.

Printing

When it comes to printing, you can print your logo with various branding elements on the surface of the corrugated fiberboard to enhance your brand identity.

Coatings

To counter specific environmental conditions, you have the freedom to apply a wax coating on the surface of the paperboard.

End Of The Line - Need Custom Corrugated Packaging?

Finding a durable and customizable packaging solution is crucial for any business. Especially when you need to ship products safely and efficiently.

This blog has provided valuable knowledge about corrugated fiberboard, including its types, uses, and advantages that offer strength, flexibility, and sustainability to meet modern packaging demands.

If you are looking for a reliable packaging manufacturer, Custom Product Packaging is here to help. Our experts specialize in producing top-quality corrugated boxes tailored to your specific needs, from size and structure to branding and protection.

Let's start a packaging journey that protects and promotes your brand. Email us at orders@customproductpackaging.com. We are ready to support your packaging goals.