Cardboard Thickness Guide: How to Choose the Perfect Option?

September 03, 2025

Brands have an overwhelming number of options when it comes to packaging boxes. Agree? The selection of the right packaging box depends on various factors. One of the most deciding factors is cardboard thickness. Right?

The thickness of cardboard plays a significant role in making the cardboard sheet stronger, ultimately making the cardboard box weighty and protecting products during storage and transit.

This cardboard thickness guide will walk you through everything you want to know to choose the right cardboard thickness. We will discuss how thick cardboard is, its weight, and types of cardboard to get sturdier cardboard boxes that meet your needs. Let's jump in!

Why Is Cardboard Thickness So Important?

Here are the grounds to help you understand why cardboard thickness matters far beyond your thoughts.

- Protection of the content

- Endure shipment

- Cut down the shipping cost

- Premium printing support

Now, let's quickly glance and unfold the reasons.

Protect The Content Inside The Packaging

The first step is to determine the packaging’s protection level. Thin cardboard sheets are not effective in this case. Therefore, you must consider perfect cardboard thickness. So it can guarantee the complete protection of the fragile and breakable items inside the box throughout the shipping process till it reaches the hands of customers.

Making Shipment Safer

The thickness of cardboard also contributes to enduring and surviving shipments. Nobody wants to receive damaged items. To counter this issue, a well-structured cardboard box makes your shipping safer and can make handling easier.

Lowers Shipping Price

The shipping cost is based on the weight of the cardboard box. More thicker the cardboard sheet is the heavier the box will be. If you are producing a cardboard box with more thickness, it will increase the weight of the box which will ultimately raise shipping costs.

Keeping a balance between the cost and thickness is essential. So, keep in mind the standard cardboard thickness and be sure the shipping cost is minimized under the specific thickness, ensuring product protection.

High-End Printing Support

Using traditional brown cardboard boxes is boring. Think out of the box. Print your brand logo with vibrant colors on the box to market your brand. Here, cardboard thickness can have a significant impact on printing. Ensure the hardest cardboard thickness is sufficient to support the printing technique.

The importance of cardboard thickness is clear. Right? It’s time to look into its measurement.

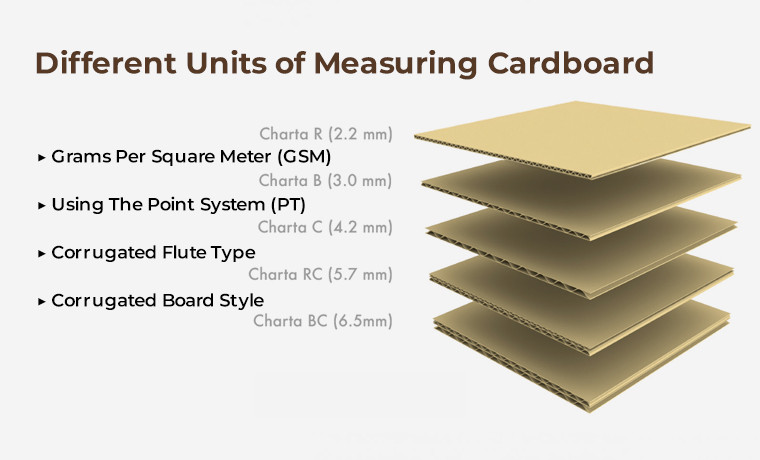

Different Units of Measuring Cardboard Thickness

There are several units to measure cardboard thickness. Here are some of the methods to help you determine their thickness using different techniques.

Grams Per Square Meter (GSM)

GSM is the most common and precise unit of measurement that is used to measure the accurate weight, length, and breadth of packaging materials like cardboard.

Here are some examples to help you understand different types of cardboard so you can measure cardboard thickness wisely using GSM.

- 35 to 55 GSM is frequently used for newspapers

- 90 to 100 GSM sheets are constantly used for printing paper

- 120 to 140 GSM thickness for cardboard sheet is usually for posters

- 210 to 300 GSM is often used for brochures

- The highest cardboard sheet of 350 to 400 GSM is repeatedly used for packaging

Using The Point System (PT)

The Point System (PT) is another technique that is utilized to measure the thickness of paper like corrugated paper which forms cardboard boxes. One point in (PT) is representing 1/1000 of an inch. The thinnest point in this system is 8pt. The thicker the (PT), the stronger the paper sheet is.

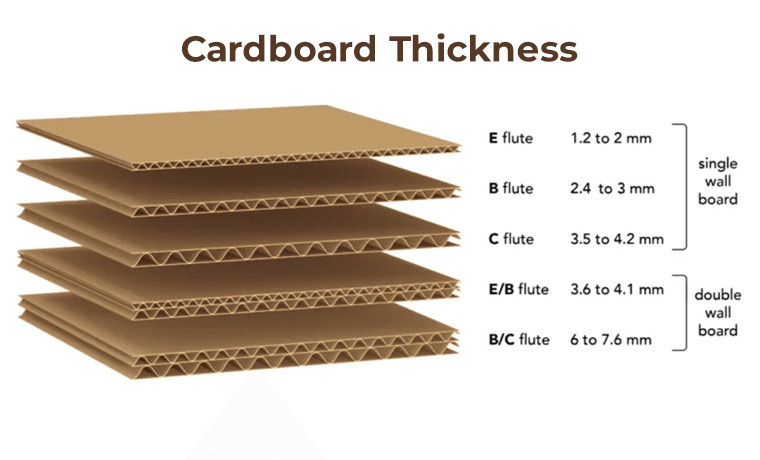

Corrugated Flute Type

The term corrugated flute refers to wavy layers of sheets that are sandwiched between liners in cardboard sheets. This is another method designed with layers to make the box more protective and insulated. The flute size does vary. Here are different types of flute sizes to help you understand the cardboard thickness chart.

- An A flute is 5 mm or 1/4" thick

- A B flute is 3 mm or 1/8” thick

- A C flute is 4 mm or 11/64” thick

- D flute is 2 mm or 17/200” thick

- E flute is 1.5 mm or 1/16” thick

- F flute is 0.6 mm or 1/32” thick

The thickness of cardboard can be determined by looking at these measurements. You can come to know how thick cardboard is in inches. You can easily calculate the cardboard box weight depending on the flute type.

Corrugated Board Style

This style is a blend of flutes and liners in corrugated cardboard boxes and can help you determine the thickness. Usually, three types of cardboard corrugated boxes are used in manufacturing different types of boxes.

They are single-face corrugated boards, double-wall boards, and triple-wall boards. You have the liberty to choose according to your needs.

Single-Face Corrugated Boards: This type of corrugated board consists of a single layer of liner combined with a layer of the fluted paper sheet. It does not require additional protection and is ideal for inner packaging content.

Double Wall Corrugated Boards: Three layers of lining covering two fluted (wavy) layers of paper is an excellent choice for heavy-duty or fragile items that require extra protection in handling and shipping.

Triple Wall Corrugated Boards: This type of corrugated board consists of four layers of inner sheets and three fluted layers. Most commonly, this packaging style is used in industrial.

So far, we have explored how to measure the cardboard thickness. Next, let’s consider the right cardboard sheet for packaging.

How to Choose the Perfect Cardboard Sheet for Packaging

These are the following factors involved when it comes to choosing the ideal packaging.

- Content type you need to pack

- Shipping Process

- Packaging Budget

- Design Process

- The Packaging Manufacturer

Now, you have a better understanding of how to measure cardboard thickness. Let’s move on to the packaging step.

The Content Inside the Box

The first step is looking at the content you want to pack in the box. Carefully perceive the value of your product, whether it is fragile or heavy-duty.

Fragile content may require additional protection. On the other hand, heavier items may require more robust boxes. You can add custom cardboard inserts or dividers to restrict the movement of the content in the box during transit. It will keep the content remain safe and sound.

Another thing is product size. You must choose a box that is perfectly fit to comfortably accommodate the product. The box should not be too large.

The Shipping Process

Shipping is another important aspect. If you are considering third-party logistics (TPL), you don’t need any packaging as they will just pick up your package, use their box, and ship it to the destination.

If you are packing your package yourself, it is your choice. Make sure the packaging is durable and offers protection to your products from getting damaged during transit.

Estimated Budget

Your shipping budget also counts. While determining the packaging cost, you must know how much your shopping cost is. Usually, the shipping cost is based on the package size and weight. Considering thicker cardboard packages may slightly raise shipping rates but more importantly, it offers extreme protection to your products.

Design Support

Customers are more likely to respond to packaging designed with captivating graphics. Here cardboard thickness combined with premium quality has a great impact and tends to print high quality on the paper. Choose a higher GSM paper to get your desired printing result if you are seeking quality image or text printing on the paper.

Consultation from Packaging Experts

You are done with all the respective knowledge about cardboard thickness. Still, if you need assistance related to your packaging project, consult with professionals experienced in dealing with paper packaging materials and utilizing modern printing methods.

Hope you have enough understanding about the thickness and weight of a cardboard box. Let's wrap up everything.

Closing Remarks

Cardboard thickness affects its strength and durability. Understanding the appropriate thickness of cardboard can help you choose the right type of packaging to meet your needs.

The perfect cardboard thickness is based on several factors, from product type and weight to the shipping process and the packaging budget. Usually, the thickness of cardboard is 3 to 4 mm, sufficient to manufacture a normal cardboard box to pack fragile items.

You need to choose the right type of cardboard sheet to get the ideal thickness for your packaging. If you are planning to select cardboard packaging for your next project, Custom Product Packaging is your ultimate partner. Want to learn more? Email us at orders@customproductpackaging.com.