Chipboard Vs Cardboard : What’s Best for Your Packaging Needs

October 15, 2025

In the realm of packaging materials, several materials are found. Each material offers distinct features and properties. A material selection can make or break. Right! In a detailed discussion about chipboard vs cardboard, which material should you go with is the question that comes to mind while selecting the most suitable material.

Keeping many factors from design aesthetics to structural integrity and product protection, this blog will help you understand the primary differences between chipboard and cardboard carrying their advantages and disadvantages and uses. Let’s get started!

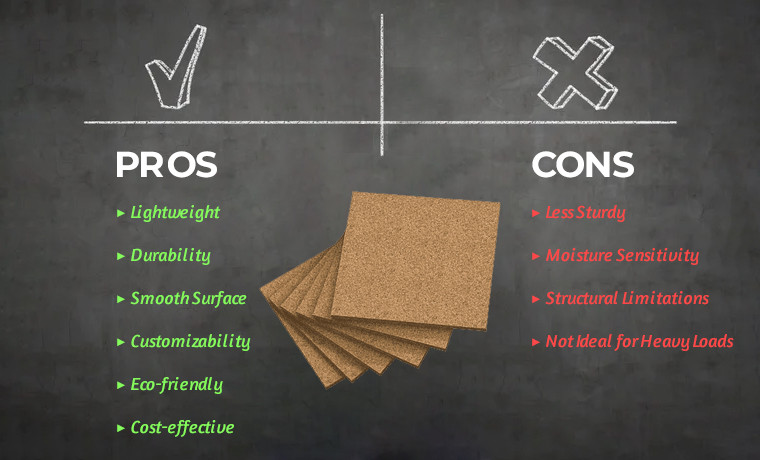

Unveiling Chipboard: Advantages and Disadvantages

The positives and negatives of cardboard are here.

Pros of Chipboard:

- Lightweight: Easy to handle during shipping and convenient to transport due to its lower weight.

- Durability: Strong in packaging even when it is not as rigid as corrugated cardboard.

- Smooth Surface: Offers a clean and smooth surface.

- Customizability: Customizable in different sizes and can be easily shaped and printed.

- Eco-friendly: Made from recycled wood pulp materials.

- Cost-effective: Offers good value for money and is less expensive than cardboard or materials like plastic.

Cons of Chipboard:

- Less Sturdy: Not as strong and durable as cardboard. Not suitable for heavy packaging.

- Moisture Sensitivity: May become weak when exposed to moisture.

- Structural Limitations: Not appropriate for structural applications or items requiring high rigidity.

- Not Ideal for Heavy Loads: This may not offer enough support for heavy-duty items.

So, you are now familiar with the gains and losses of chipboard. The next turn is of cardboard. Check their pros and cons.

The Applications of Chipboard

Chipboard is a highly versatile material used in various applications.

- Packaging: Ideal for lightweight packaging like cereal boxes and shoe boxes.

- Bookbinding: Chipboard provides a sturdy and smooth surface and is used for making durable book covers.

- Backing: Often utilized as backing for calendars and picture frames due to its rigid yet thin structure.

- Crafting: Popular in DIY projects and scrapbooking as it is easy to cut and decorate.

- Furniture: Use in low-cost furniture as the backing of shelves and drawer bottoms.

- Displays: Appropriate for creating retail displays, signs, and promotional materials.

- Game Board: The chipboard is durable and makes a sturdy base for board games.

- Model Making: Used in architectural and hobbyist models for its ease of cutting and shaping.

Also Read This: A Brief History of Cardboard: Who Invented Cardboard

Exploring Cardboard: Benefits and Drawbacks

The advantages and disadvantages of cardboard are here.

Pros of Cardboard:

- Strength and Durability: Strong and can support heavy loads when corrugated.

- Lightweight: Easy to handle due to its lightweight nature.

- Customizable: Easy to cut, fold, and print on carrying various branding aspects.

- Shock Absorption: Provide cushioning to protect the content inside the box during transit when made with corrugated layers.

- Cost-efficient: Affordable materials for packaging and shipping boxes.

- Recyclability: Highly recyclable.

Cons of Cardboard:

- Weight Limitation: It does not provide sufficient support and is not suitable for heavier items.

- Flammability: Highly flammable and can be easily burnt when exposed to fire.

- Water Absorption: Cardboard can absorb water and lose its strength which can lead to potential damage to the contents.

- Environmental Impact: Being recyclable has some environmental impact.

The Applications of Cardboard

Here are some common uses of cardboard.

- Packaging: Widely used to produce folding cartons and product packaging.

- Storage: Good to manufacture boxes for organizing and storing items.

- Crafting: Quite popular in DIY projects, arts, and crafts.

- Advertising: Used for display stands, signs, and promotional materials.

- Recycling: Easy to recycle and turn into new cardboard products.

Now, you know what chipboard and cardboard are. Let’s look at the primary differences between them to understand them better.

Chipboard Vs. Cardboard: Core Differences

The debate between chipboard and cardboard has no end. Both of these materials are different from each other in terms of their characteristics and applications. Here are the primary differences.

| Features | Chipboard | Cardboard |

| Composition | Made from recycled paper pulp, compact and dense | Consists of a corrugated layer sandwiched between flat layers |

| Strength | Less sturdy, more flexible | Stronger and more rigid |

| Best for | Packaging | Shipping boxes, cartons, and retail packaging |

| Thickness | Typically thinner and available in various weights | Often thicker due to the corrugated layer |

| Surface | Smooth and clean | May have a rough texture |

| Recyclability | Recyclable | Highly recyclable |

Clear with the differences? Which material should you choose for packaging? Read on.

How to Choose the Right Material for Your Packaging Needs

Both chipboard and cardboard, when weighing, can help us determine the right material selection. Here are some factors involved that can help you make the right decision.

- Product Nature: The first step that can help you select the right material is your product nature. Evaluate your product type from various aspects, including weight, fragility, and size.

- Shipping Requirements: Determine whether the product is heavier or fragile. The large items may require additional protection during transit. Choosing corrugated cardboard for long-distance shipping is appropriate and far better than chipboard as it can withstand hardship.

- Customization: Both cardboard and chipboard are customizable with plentiful options.

- Design: Cardboard allows to creation of boxes with captivating designs and premium-quality printing.

- Branding: Designing cardboard boxes with branding attributes can resonate with a brand to a wider audience.

- Budget: It is essential to balance the costs. Chipboard is cheaper for lightweight products However, if your products are valuable or delicate and require protection, then cardboard being inexpensive is an excellent choice that pays off and allows you to ship your product with care.

The comparison is over now. Let’s summarize it.

Recap!

The choice between chipboard vs cardboard entirely depends on your packaging needs. In terms of customization options, rigidity, and environmental impact, chipboard is a considerable option. If you are looking for strength and durability then cardboard is your best companion.

Chipboard and cardboard both are versatile materials and are used in various applications. Understanding the unique properties of each material can help you make the right choice to fulfill your packaging needs.

Here Custom Product Packaging bringing the ultimate packaging solutions is your right packaging partner that uses super-quality materials like chipboard, cardboard, and kraft for custom boxes to protect your products during display and transit. Shoot us an email via orders@customproductpackaging.com.