Exploring Screen Printing: Method, Applications, and Pros

September 08, 2025

Several manufacturing businesses from different industries over the years have been featuring printed images or text on their fabric products, like t-shirts. Are you also running a textile industry and want to make your products visually appealing? If yes, you are in the right spot!

What type of printing method are you using to print text or images on the fabric? Is it sparkling, adaptable, and affordable to produce your bundle of printed t-shirts? If not, don’t worry! Keep on reading.

To meet all your printing needs, screen printing is the solution! It is the right choice to produce vibrant and flexible results while maintaining versatility, saving cost, and making tons of copies of the printed design.

Wondering? What is screen printing? Read on to know everything about this printing type. Let’s dig in!

What Is Screen Printing?

Screen printing, also known as serigraphy, is a flexible printing technique in which the link is applied through a mesh screen that holds stencils. The stencils allow the creation of a printed design on the surface of substrates by placing the precise amount of ink in the specific area. As a result, the design or text is printed with a high level of color vibrancy.

This versatile method can be used in a wide range of industries on various materials such as fabric, wood, paper, and metal. You have the liberty to use this printing method multiple times to achieve vibrant colors and images on the desired material. Simple!

You have an understanding of this printing method. Right? Great. How to start screen printing? Now, let’s break down its process and see how it works.

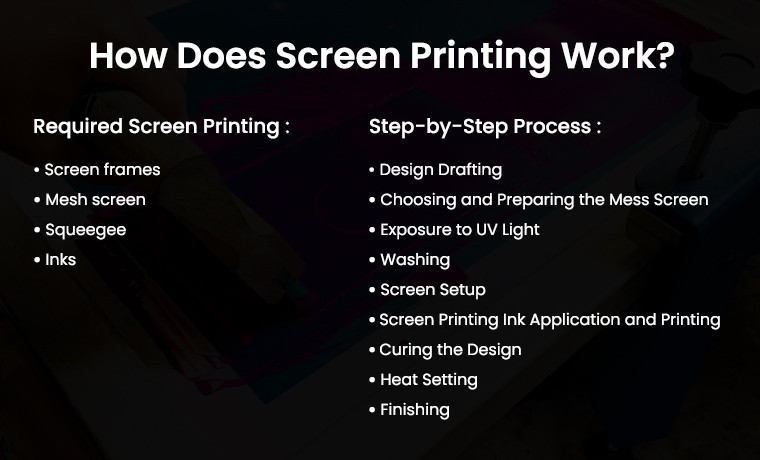

How Does Screen Printing Work?

Before delving into the process of screen printing, take a look at the equipment required to complete the whole process.

Required Screen Printing Equipment

- Screen frames

- Mesh screen

- Squeegee

- Inks

Step-by-Step Process of Screen Printing

The process of screen printing comprises the following steps:

- Design Drafting: The first step of the screen printing process begins with the text or original image. The prints of the design are placed on the transparent film.

- Choosing and Preparing the Mess Screen: The next step is to select a mesh to start the silk screening operation. It is based on the material used for printing, like fabric.

- Exposure to UV Light: Shelter the mesh screen with a light-sensitive layer and then expose it to UV light. The light will harden the emulsion.

- Washing: The washing step comes after exposure. It involves washing the design with water to remove the unexposed emulsion, leaving the stencils open.

- Screen Setup: The prepared screen is placed on the printing press. The material, like a t-shirt, is placed under the screen.

- Screen Printing Ink Application and Printing: The ink is placed on the screen, and a squeegee is moved with consistent pressure to press ink for even ink application through the stencils' open areas onto the material's surface.

- Curing the Design: After printing, the ink needs to be dried to set permanently using a heat press or air drying.

- Heat Setting: Proper curing and drying ensure the print is durable and can withstand washing.

- Finishing: The prints are inspected to maintain quality and ensure they are complete and spot-free.

Got the idea of the screen printing process? Excellent. Let’s move towards its types.

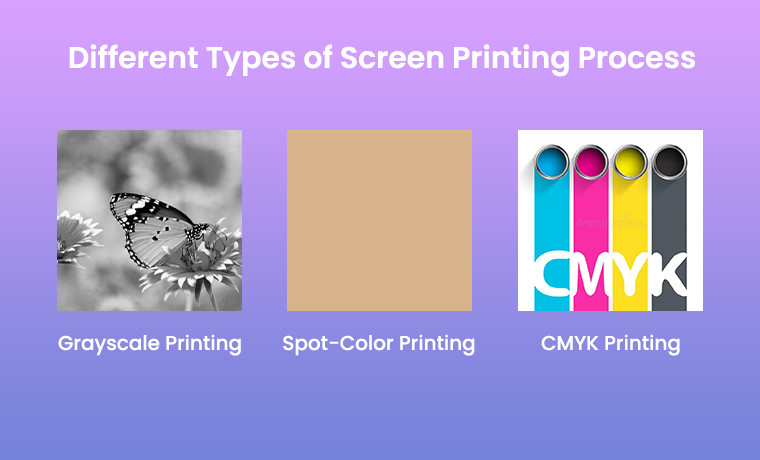

Different Types of Screen Printing Process

The screen printing process offers different finish results, which vary. It is better to understand different types of screen printing processes and choose the right technique that fulfills the requirements of your project.

1. Grayscale Printing

This outstanding printing technique uses varying shades of gray to create images. The gray shades using only black are achieved by varying the concentration of black ink.

2. Spot-Color Printing

The spot-color printing method uses premixed inks to achieve specific colors in a printed design. Without relying on the CMYK, it uses individual inks for each chosen color to gain a precise, vibrant spot of colors and special effects in printed materials.

3. CMYK Printing

CMYK stands for Cyan, Magenta, Yellow, and Key (Black). This CMYK or four-color printing technique creates a wide range of colors by combining four inks.

Next, let’s discuss the key benefits of using screen printing.

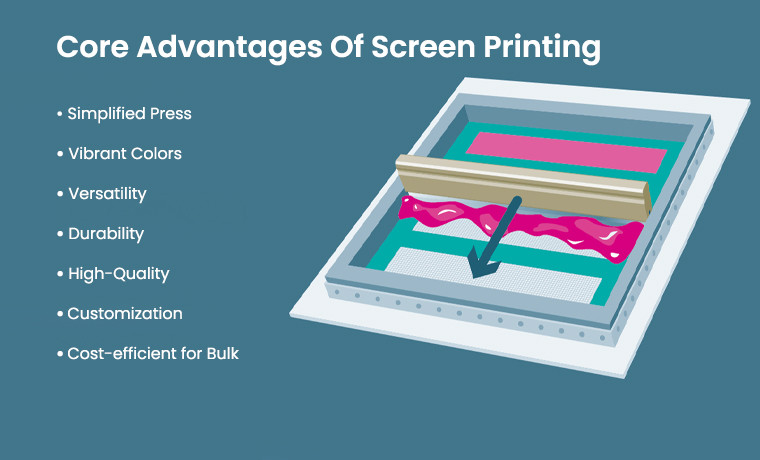

Core Advantages Of Screen Printing

The significant benefits of screen printing are explained here:

- Simplified Press: The screen printing process is simple. Whether it is done manually or through an automatic system, it is a straightforward process.

- Vibrant Colors: Produces vivid and bright colors.

- Versatility: Appropriate for a wide range of materials such as ceramics, textiles, paper, metal, and wood.

- Durability: The ink used in the silkscreen printing is thick and stands up to washing and wearing.

- High-Quality: Produces sharp and high-quality prints with precise details.

- Customization: Offers endless customization options and can be used for simple and complex designs.

- Cost-efficient for Bulk: Cheaper for large volume runs.

Read Also: What is The Difference Between Offset and Digital Printing?

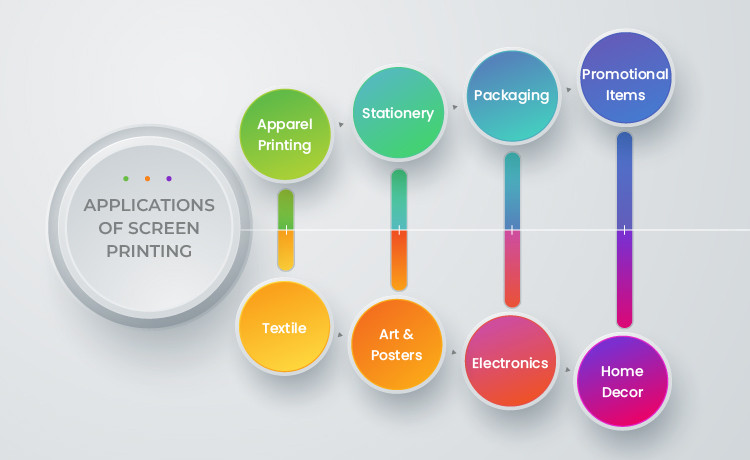

Applications Of Screen Printing

The printing technique is incredibly versatile and used in a wide range of applications. Below are some applications and uses:

- Apparel Printing: T-shirts and hoodies are the most common apparel for which this printing method is used for vibrant and durable designs. Team logos, names, and numbers on jerseys printed on sportswear using this technique are examples for better understanding.

- Textile: Prints continuous patterns on rolls of fabric.

- Stationery: Custom covers and designs on notebooks or various stationery items including business cards or greeting cards.

- Art and Posters: Artists use this printing process to create limited-edition prints. High-quality posters for concerts or movies are examples of this printing method.

- Packaging: This printing technique is ideal for creating product labels placed on bottles, glass cream jars, and other packaging options. You can find printed designs or logos on the packaging boxes using this printing method.|

- Electronics: Prints conductive inks on circuit boards. It includes printing symbols and letters on keys.

- Promotional Items: For embellishing headwear with logos or artwork as promotional items. Prints custom for events or giveaways on custom bags and totes.

- Home Decor: Prints custom designs on pillows and cushions by adding unique patterns to the fabric.

We have covered a lot about screen printing. Still confused if it is different from sublimation or not. Let’s reveal this secret in the next part!

Sublimation Vs. Screen Printing

Let’s differentiate between screen and sublimation printing.

| Features | Sublimation Printing | Screen Printing |

| Method | Uses heat to transfer dye onto materials | Uses a stencil and squeegee to apply ink onto materials |

| Materials | Primarily polyester fabrics and coated surfaces | Various materials such as fabric, paper, wood, and metal |

| Color Quality | Produces vibrant and full-color prints with gradients | Produces vivid colors |

| Durability | Colors are embedded in the fabric, resulting in high durability | Long-lasting |

| Design Complexity | Great for complex and detailed images and photos | Ideal for simple to moderately complex designs |

| Cost-efficiency | Cost-effective for small runs and custom items | Cost-effective for large runs |

| Finish | Smooth finish | A slightly raised print |

Now, take a glance at another comparison.

DTG Printing Vs. Screen Printing: Primary Differences

Here is a comparison of screen and digital printing.

| Features | Digital Printing | Screen Printing |

| Method | Uses inkjet technology to print directly onto fabric | A stencil and squeegee are used to apply ink to materials |

| Materials | Best for 100% cotton or cotton blends | Various materials, from fabric and paper to wood and metal |

| Color Quality | Produces rich and full-color prints with gradients | Produces bright colors |

| Durability | Good durability but may fade over time | Highly durable |

| Design Complexity | Excellent for complex and detailed images and photos | Ideal for simple to moderately complex designs |

| Cost-efficiency | Cost-effective for small runs and custom items | Cost-effective for large runs |

| Finish | Soft feel | A slightly raised print |

| Setup Time | Minimal setup. No need for screens | Requires setup of screens and alignment |

So, all done with the understanding. Let’s conclude it!

Closing Thoughts

Got an overview of what is screen printing? Hopefully, yes. It is a reliable method that involves transferring images or designs through a stenciled mesh screen onto various surfaces. This technique is used in a wide range of industries such as textiles and graphics, as it can efficiently produce high-quality prints. For custom apparel and artwork, this printing practice is ideal.

To get vibrant prints with finishes for your next project, join hands with Custom Product Packaging and let our printing specialists know your needs. Request an instant quote today by writing us a short email at orders@customproductpackaging.com. You can turn your dream printing into a vision by partnering with us. Contact us TODAY!