A Thorough Flexible Packaging Printing Guide

November 25, 2025

Keeping your packaging budget in control and offering versatility for various products, from food and beverages to pharmaceuticals and personal care items, what packaging printing option do you think is better? Don’t you want your products to look prominent on the shelves? If so, you must try flexible packaging printing to catch the attention of the maximum consumers.

This blog will delve into flexible packaging printing to help you better understand its types and processes. Ultimately, you can decide which type of packaging printing is suitable to meet your needs.

What is Flexible Packaging Printing?

Flexible packaging printing refers to applying packaging design, text, and graphics onto the packaging materials. It is an excellent choice for food packaging, pouches, and bags made from plastic films. Flexible packaging made from foil is good for packing snacks or other items that require a barrier.

The objectives of preferring printed flexible packaging are to:

- Enhance the visual appeal of product packaging

- Provide necessary product information

- Build a powerful brand identity

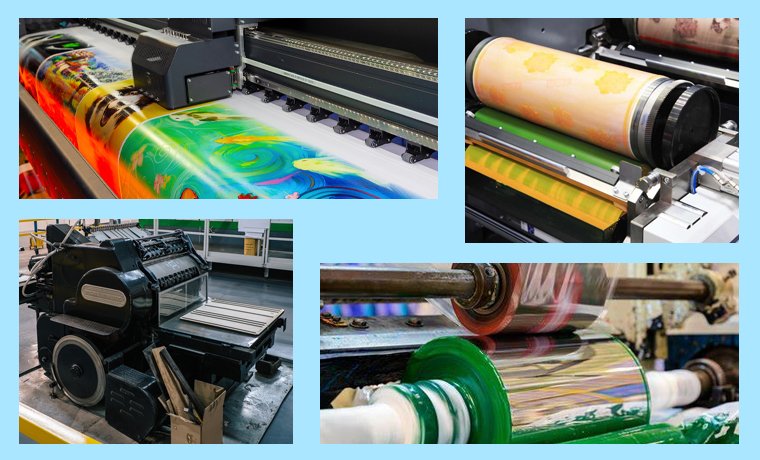

Four Types of Flexible Packaging Printing

The most common types of printed flexible packaging are here.

1. Flexography Printing

Also known as flexo printing, it is the most common printing method. Instead of solid plates, flexible relief plates made of rubber are used in its process.

The pros flexographic printing offers are such as:

- Easy setup process

- Cost-effective

- High-speed production

- Enhanced image quality

Handling high-volume printing makes it ideal for packaging such as:

- Plastics pouches

- Snack bags

- Stand-up pouches

- Also good for printing:

- Labels

- Tissue paper

- Envelopes

- Other flexible substracts like plastic, films, metallic foil, and paper

2. Digital Printing

An inkjet-based modern printing technique that transfers digital-based images directly onto various media. In its process graphics and branding elements are applied on different plastic substrates.

It eliminates the need for printing plates and makes the whole printing process faster. This improves turnaround time and reduces waste production. Digital files in the form of PDFs or images are directly sent to the printer, and then they are printed in no time.

Benefits of Digital Printing

Digital printing is beneficial for:

- Low set-up cost

- Sustainability

- Quick turnaround time

- High-end print quality

- Some examples of digital printing are:

- Short-run books

- Blister card packaging

- Posters

- Brochures and flyers

- Magazines

- Business cards

- Catalogs

- Stickers and labels

- Photo prints

3. Rotogravure Printing

A type of intaglio printing process shortened to gravure is a unique printing method. In this printing method, the images are engraved onto the surface and the engraving is completed onto the cylinder. Finally, the image is "sunken" into the printing surface. An excellent choice for producing consistent, detailed images and long print runs.

Rotogravure printing is best for:

- High-quality image

- High-speed production

- Consistency

- Durability and longevity

- The applications of rotogravure printing are:

- Catalogs

- Newspapers

- Advertising materials

- Calendars

- Banknotes

- Stand up pouches

- Postage stamps

- Wallpaper

Also Read: What You Should Know About Flexible Packaging

4. Lithography Printing

Lithography is a versatile printing process in which the oil-based ink is applied to the flat surface of a metal plate or limestone. This creates images using a greasy substance of wax or a special type of ink. Water is spread over the surface, avoiding the greasy areas and bonding with the non-greasy portions.

Lithography printing is superb for:

- High print quality

- Customizable

- Cost-efficient

- Versatility

The lithography printing is suitable to produce:

- Packaging

- Books and magazines

- Posters

- Stand up pouches

- Maps

- Fine art

Flexible Packaging Printing Process

There are some steps involved when it comes to exploring how the flexible packaging printing process works.

-

Pre-Press Setup

Get your flexible packaging printing machines ready to print design files. Proper prepress preparation can help you achieve the desired quality of the final printed products. Make sure all the settings are finely set up.

-

Printing and Monitoring

Initiate the printing process using the appropriate flexible packaging printing equipment. Begin the process even if you have flexible packaging printers. Keep monitoring the printing quality. Check the colors are nicely printed.

-

Post-Print Processing

The final touch of the print materials starts when you need to apply laminations or coating on the surface. It can enhance the durability of your printed materials.

-

Final Inspection

Conduct a final assessment of your printed materials. Make sure it is error-free and perfect according to the specifications you need.

How to Choose the Right Printing for Your Flexible Packaging

When it comes to choosing the most flexible packaging printing to fulfill your needs, it is totally based on your requirements and budget. You can choose flexography printing for faster print runs if your budget is limited. However, it may not be suitable to produce high-quality photographic images.

If you have a large budget, then you can choose lithography. It is an expensive printing method but can produce excellent-quality images. If you are unsure which printing method to use, you must approach a reliable packaging supplier like Custom Product Packaging to discuss your packaging and printing needs.

Conclusion

Flexible packaging printing is an essential aspect of modern packaging solutions that enhances product shelf appeal while offering attractive packaging design. Embracing technology, each printed flexible packaging type offers advantages and disadvantages. The purpose is to elevate a brand and enhance consumer engagement.

Providing excellent packaging and printing services to clients, Custom Product Packaging's printing specialists can guide you professionally. Just email us at orders@customproductpackaging.com and talk to our experts to get the design that truly expresses the essence of your brand.