8 Practical Methods of Making Cardboard Waterproof in 2026

January 01, 2026

Cardboard made from wood pulp is a durable and strong material, right? However, it loses its shape and durability when it is wet.

Ever had a cardboard box disintegrate in the rain? This makes it dysfunctional. But worry not! This won’t happen again, as this blog will discuss:

- How to make waterproof cardboard

- Practical tips to maximize results while waterproofing cardboard.

- Core factors before making waterproof cardboard.

Ready to extend the life of your cardboard? Gear up to make your cardboard last. Let’s start with the most efficient methods.

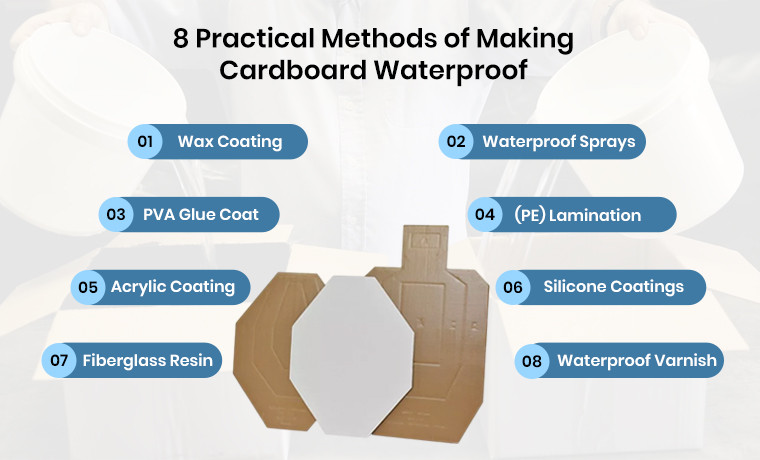

Different Ways to Make Waterproof Cardboard

Effective and proven ways to make cardboard waterproof are:

- Wax Coating

- Waterproof Sprays

- PVA Glue

- Polyethylene (PE) Lamination

- Acrylic Coating

- Silicone Coatings

- Varnish or Sealant

- Fiberglass Resin

Wax Coating - Conventional Waterproofing Method

A conventional method in which a thin layer of paraffin wax is involved. By forming protective layers to fill the pores of cardboard, it protects cardboard from moisture damage when applied to the surface of the cardboard.

As a result, the content inside the coated cardboard boxes remains safe from dampness and spills. Ideal for products such as food or industrial goods that require extreme protection from moisture.

How to Wax Coat to Make Cardboard Waterproof?

These are the following steps to make waterproof cardboard.

- Use a double boiler to melt the wax.

- Clean and dry the cardboard.

- Apply the melted wax onto the cardboard.

- Let it absorb, cool, and harden.

- Buff the surface with a piece of cloth for a smooth finish.

Waterproof Sprays - Quick, Easy and Efficient

Want to make cardboard proof easily in no time? No other than user-friendly waterproofing sprays are handy choices.

They are often used to protect outdoor furniture and other items from external damaging factors. Easy to use and requires no special skills.

How to Spray on Cardboard to Make it Waterproof?

Ensure these steps are followed when applying waterproof spray to make your cardboard waterproof.

- Clean the cardboard. Ensure it is free from dust and debris.

- Choose a clear acrylic spray coating.

- Shake the acrylic spray can well.

- Hold the spray can and apply the first coat.

- Spray it at an 8 to 12-inch distance from the cardboard.

- Apply a light and even coating.

- Let it dry completely. It may take 15 to 30 minutes.

- Apply additional coating for better protection. Let each coat dry before applying the next one.

- Inspect the cardboard if any spot is missed.

PVA Glue Coat - Wallet-Friendly Waterproof Solution and Easy DIY

PVA Glue, or polyvinyl acetate glue, is an inexpensive technique to make cardboard waterproof. Just use a mixture of water with PVA glue to make cardboard waterproof.

The glue will dry clear without affecting the appearance of the cardboard. An excellent choice for crafts and school projects.

How to Make Cardboard Waterproof Using PVA Glue?

Follow these easy steps to apply PVA glue on cardboard to make it waterproof.

- Mix the PVA glue well with water in a container.

- Use a brush to apply an even thin layer of glue mixture on one side of the cardboard.

- Let the cardboard side dry completely.

- Flip the cardboard and apply the glue mixture to the other side. Allow it to be dried.

- Apply an extra layer of glue mixture to seal the edges of the cardboard. Let them dry.

Polyethylene (PE) Lamination - Sophisticated Waterproofing Choice

-lamination.jpg)

Laminating cardboard means protecting it through a thin layer of polyethylene plastic sheet and enhancing its properties. This makes it suitable for diverse applications.

A thin sheet of PE film is water-resistant by nature. It protects cardboard from dampness. It prevents the cardboard from getting damaged when PE is bonded to the cardboard surface through heat and pressure. This creates a protective layer to improve the cardboard’s durability and resistance to moisture.

How to Laminate the Cardboard to Make it Water-Resistant

- Measure and cut the self-adhesive laminate sheets. Cut it slightly larger than your cardboard piece.

- Apply the plastic sheet carefully onto the cardboard.

- Press the sheet and smooth it out. Make sure there are no air bubbles.

- Trim an excessive laminate sheet around the edges.

- Flip the cardboard and repeat the same process on the other side of the cardboard.

- Use clear washi tape to seal the edges for extra protection.

Acrylic Coating - Chic and Easy Waterproofing Method

Acrylic coating for cardboard is a protective layer applied to cardboard to enhance its durability, water resistance, and appearance. It's a versatile solution used in various applications, from packaging to art projects. This acrylic coating is especially ideal for food and electronics packaging, where the utmost water resistance is required.

How to Use Acrylic Coating for Waterproofing Cardboard?

Follow these quick steps to create a waterproof cardboard.

- Choose a clear acrylic coat. You can get it easily from a hardware store.

- Apply the first even coat on the cardboard surface and let it dry completely.

- Paint an additional layer of acrylic layer for extended protection. You can apply 2-3 coats. Let each coat dry.

Silicone Coatings - Sturdy and Reliable

Creating a surface over the cardboard, silicone coatings offer superb water-repellent properties that withstand moisture and cannot penetrate. This coating is highly effective for specialized applications to make cardboard more durable and resistant to wear and tear.

How to Apply Silicon Coating on Cardboard?

The following steps can help you ensure that silicon coatings are applied to cardboard.

- Dry and clean the cardboard. Make sure it is dust-free.

- Shake the silicon coating can well.

- Apply a thin silicone layer evenly with a caulk gun or brush.

- Apply it fully to cover its edges and corners.

- Smooth it with a spatula.

- Let the layer be completely dried.

- Apply another layer for additional protection.

- Leave the coating for 24 hours. Let it dry.

- Check by sprinkling water.

Also Read: Guide To Using Waterproof Cardboard For Your DIY Projects

Waterproof Varnish or Sealant

Waterproof varnish, also known as waterproof lacquer, is a coating applied over the cardboard to make it waterproof.

It forms a thin layer on the cardboard surface that acts as a protective shield and offers excellent protection against moisture. Further, it prevents water from penetrating and damaging the cardboard material.

How to Apply Varnish or Sealant to Make Cardboard Waterproof?

Go with these simple steps to use varnish or sealant to construct a waterproof cardboard.

- Choose a clear varnish sealant for the cardboard.

- Use a brush to apply a light and even coat over the cardboard.

- Let it dry as instructed.

Fiberglass Resin - Hard-Wearing Waterproofing and Outdoor Use

Fiberglass resin is a powerful waterproofing agent that creates a waterproof barrier to protect cardboard from moisture damage. It adds more strength and rigidity to cardboard. Its durability makes it more resistant to wear and tear in challenging environmental situations.

How to Use Fiberglass Resin to Make Cardboard Waterproof?

These are the following steps to help you apply fiberglass resin in making waterproof cardboard.

- Wear gloves.

- Mix resin well with the hardener as directed.

- Use a brush to apply the resin mixture to the cardboard.

- Let it go fully dry. DONE!

Now you are familiar with 8 proven methods to make waterproof cardboard. Confused which method you should choose? We have made this easy by drawing a comparison of these effective methods in the next part.

Brief Comparison Between Different Cardboard Waterproofing Techniques

See the table below to differentiate 8 practical methods of making waterproof cardboard.

| Features | Difficulty Level | Pros | Cons | Cost |

| Wax Coating | Medium | Low-cost, effective, safe, and non-toxic for food use. | It might soften in hot conditions. Waxing extensive areas can be somewhat difficult. | $0.10 to $0.25 |

| Sprays | Easy | Easy to apply. Comes in diverse formulations. Provides quick results. | Reapplication might be needed over time. Some sprays may result in a sticky layer. | $0.15 to $0.30 |

| PVA Glue | Easy | Less expensive. Can be easily | Breaks down easily when | $0.05 to $0.15 |

| Lamination | Medium | Forms a smooth and long-lasting waterproof layer that shields against dirt and stains. | Requires laminating tools and might be less adaptable than other options. | $0.20 to $0.50 |

| Acrylic Coating | Easy | Provides a lasting and flexible coat. Can be applied in a range of thicknesses. | May need multiple coats and excessive bending could cause peeling over time. | $0.15 to $0.30 |

| Silicone Coatings | Medium | Super strong, durable, and waterproof to resist high temperatures. | Pricier than other methods and difficult to achieve an even application. | $10 to $30 |

| Varnish | Medium | Adds water resistance and improves durability. Non-toxic and easy to apply. | Can become yellow over time and may crack when bent. | $10 to $50+ |

| Fiberglass Resin | Medium | Provides sturdy and tough waterproofing solution. Builds a strong and lasting surface. | Requires good ventilation. Application may be messy and carry potential toxic risks. | $20 to $60 |

Top 3 Proven Tips for Making Waterproof Cardboard Efficiently

Every waterproofing cardboard method has pros and cons and they are effective in different situations. To help you make cardboard waterproof, here are the top tips below:

Tip 1: Apply Multiple Coats for Enhanced Protection

Apply more than one coating to make the cardboard stronger and durable.

Tip 2: Let Each Layer to Dry Completely

Wait for each layer to dry before applying the next layer.

Tip 3: Reserve Cardboard for Indoor Applications

Waterproofed cardboard can last longer when it is kept out of heavy rain.

Key Factors to be Considered When Making Waterproof Cardboard

Keep in mind these core factors before choosing the most effective method.

Best in Uses:

Outdoor projects require more durability and protection (e.g., fiberglass or lamination). Wax coating or waterproof spray can be a good choice for indoor projects or light packaging.

Cost:

The cardboard waterproofing methods, such as PVA glue do not bother your pocket as it is an affordable option. While other methods, like fiberglass resin require much investment.

Skill and Expertise:

Laminating or using fiberglass resin requires good skill, practice, and care. Ensure the method you choose is comfortable and easy to apply over the cardboard to make it waterproof.

Closing Remarks

Hopefully, you got your answer on how to make waterproof cardboard. You can do it by applying a layer of a waterproof sealant or using wax to create a barrier against moisture. This ensures the cardboard material remains durable and functional during wet conditions.

As a result, cardboard remains safe from damage when it is exposed to moisture. Extending cardboard lifespan makes it suitable for outdoor use.

Looking for durable cardboard solutions? Reach out to Custom Product Packaging for expert guidance. Just email us at orders@customproductpackaging.com. Why wait? Call us NOW!