A Quick Guide to Packaging Automation

September 24, 2025

Relying on manual labor is good, but it takes a lot of time to process the production. Further, it may also cause delays in orders. In a fast-paced world, don’t you want to make this process faster and deliver your orders timely? What solution do you think is better to streamline your production process?

In this case, packaging automation emerges as a game changer that can help make your production smoother and faster with efficiency and accuracy while reducing costs.

This blog will help businesses understand the basics of automated packaging solutions, offering enhanced efficiency and consistency under less labor to complete production. It can help companies stay in the competitive market. Let's dig in!

Understanding Packaging Automation

Automated packaging refers to using automatic packing machines and technology to streamline the automated process and handle packaging tasks without labor involvement. This process includes filling, sealing, labeling, and wrapping products. Sorting and boxing items are part of the process.

The primary goals of automated packaging are to boost efficiency, enhance product quality, and improve safety with less manual labor costs in the whole packaging process. Businesses in the industry ensuring consistent product quality can achieve faster production rates and minimize errors through this innovation.

After knowing what packaging automation is, let’s move to explore its various components.

Key Components of Packaging Automation

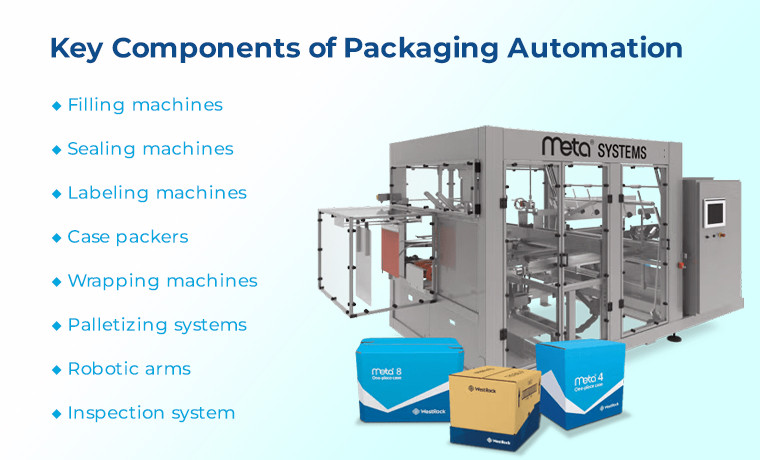

Several components of packaging automation are here.

- Filling machines: Automated fillers ensure accurate dispensing of liquids and powders.

- Sealing machines: The containers are securely closed by heat sealing.

- Labeling machines: This labeler machine applies labels to product packaging quickly.

- Case packers: Help to pack individual products into cases or folding cartons.

- Wrapping machines: They help wrap your products with film and other materials, ensuring maximum protection during shipping.

- Palletizing systems: The automated palletizers stack and put your products in orders on pallets to ensure efficient storage and shipment.

- Robotic arms: Help in picking, placing products, or assembling components.

- Inspection system: Sensors, cameras, and other devices come under this system to check the quality, weight, and correct labeling on packaging.

Now, you know the components. It’s time to discover its advantages.

Why Automated Packaging is Essential

Here are the key benefits of packaging automation that can remodel your packaging business operations.

Increased Efficiency and Speed:

With the help of automated box packaging systems, you can make the production process faster with less required labor. It helps you quickly handle tasks from filling and sealing to labeling and wrapping.

Budget-Savings:

It helps save your packaging costs in terms of wastage and rework where you perform one task, ensuring it is good to go, which reduces mistakes and minimizes costs.

Improved Accuracy and Consistency:

This packaging automation allows you to handle your packaging from every aspect while reducing errors, which brings consistent quality and fewer errors when making the packaging for the products.

Enhanced Safety:

Your workforce remains safe from risks of injuries while operating the automated packaging system. Once a laborer starts the process, leave everything to the automatic packing machine. Just sit and let the machines do the rest of the job.

Flexibility and Scalability:

This technology can scale up your fluctuating market demands, enabling you to reshape the evolving marketing conditions.

Reduced Labor Costs:

A small number of human resources can operate product packaging machines to streamline production. It can help complete orders by automating repetitive tasks.

You are now aware of the benefits of packaging automation. The next step is to select the right packaging automation to help your production faster.

Choosing the Perfect Packaging Automation Solutions to Streamline Your Business

What type of automated packaging equipment or machine you need is actually based on the need of your products, process, and productivity objectives. The required space in the warehouse and your budget also matter.

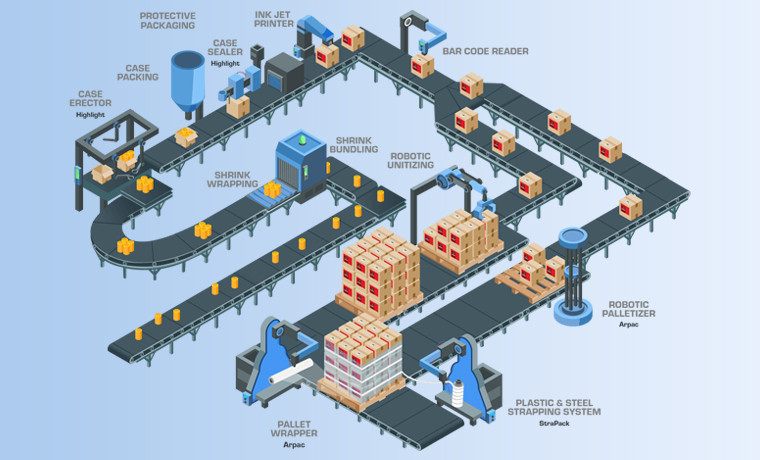

- Shrink and Film Wrapping Machines: A reliable automatic shipping wrapping machine is ideal for many products, from trays, bottles, and pads to jars, bags, and custom pouches. It runs your production process efficiently and consistently.

- Automatic case erectors and sealers: These machines make your packaging process easier by ensuring the cases are formed and sealed securely and consistently.

- Conveyor systems: These systems reduce manual intervention and transport your products smoothly through the packaging line.

Many types of packaging machinery are available in the market. From cardboard box filling and automatic case erectors to auto-bagging machines and heat shrink tunnels, plentiful options are discovered. Make a wise decision in picking the right packaging automation machine to fulfill your needs.

Let’s conclude it.

Last Thoughts

More than just a trend, packaging automation is a game changer and shaping the future. It significantly enhances your efficiency and accuracy in the production process which leads to reduced labor costs and improved consistency.

Businesses relying on manual processes can optimize their production and streamline packaging operations by embracing automated packaging solutions and leveraging its perks to minimize costs, deliver products faster, and achieve faster turnaround time.

To meet all your packaging needs, no other than Custom Product Packaging is the big name that can help you achieve your market demands. Shoot us a quick email at orders@customproductpackaging.com to share your requirements. We promptly respond.