Polyethylene vs Polypropylene: A Clear Comparison

September 11, 2025

Heard about two plastic kings, polypropylene and polyethylene? If yes, Great!

Both these plastics are present in our daily lives. Undoubtedly, they seem quite similar, but the fact is that they both differ from each other based on their characteristics. Stay here. This blog will help you learn about polyethylene vs polypropylene and understand which is better.

Your thoughts will be clear to make the right choice and use them according to your needs in your life. Here you go!

Polyethylene and Polypropylene: What Exactly They Are?

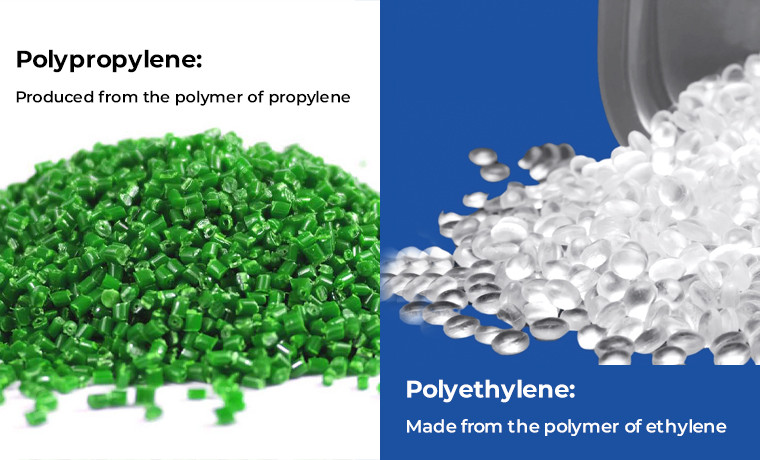

Both polyethylene and polypropylene, made from repeats of single molecules, are polymers. Based on chemical properties, they are distinctive. In short:

- Polyethylene: Made from the polymer of ethylene

- Polypropylene: Produced from the polymer of propylene

This slight difference of polymer between them makes them distinct from each other. Here, neglecting their unique properties, uses, and applications is impossible. Take a look around your place. You can find them in products made from different types of plastic. But wait here to discuss their properties.

Molecule Structure

PE and PP plastic are part of our daily routine products. They belong to the same family of thermoplastics. They can be easily processed by using thermoplastic equipment and utilizing techniques. Injection molding, blow molding, extrusion, and thermoforming are the techniques used.

Properties of Polyethylene

It is known for its excellent chemical resistance and low moisture absorption. Its properties are here.

- Lightweight: Lightweight and easy to handle.

- Chemically resistant: Resists many substances. Suitable for containers and pipes.

- Melting Point: Typically ranges between 115-135°C.

- Flexibility: More flexible than other plastics like polyvinyl chloride (PVC).

- Low Moisture Absorption: Maintain its characteristics in humid conditions.

- Insulating Properties: Excellent electrical insulator.

Want to know what types of products are created using polyethylene? Read on.

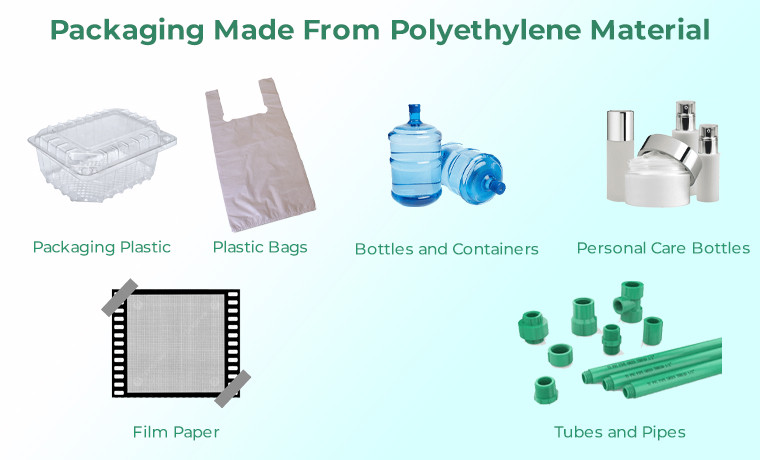

Packaging Made From Polyethylene Material

Polyethylene is found in various packaging materials around us.

- Packaging Plastic: Bubble wraps, as part of the family offer cushioning and protection to fragile items.

- Plastic Bags: Lightweight and stronger bags are created.

- Bottles and Containers: Milk jugs and detergent bottles are produced. They are stronger and resistant to impact.

- Personal Care Bottles: Shampoo bottles and lotion containers are made.

- Film Paper: To preserve food items, paper grocery bags made from thin and flexible materials are ideal.

- Tubes and Pipes: Manufactures tubes and pipes. Tubes for toothpaste and gels are an example.

Let's explore the characteristics of polypropylene. There you are.

Properties of Polypropylene

Here is the rundown.

- Lightweight: Low density and easy to handle.

- Toughness: Offers excellent resistance to impact and stress.

- Flexibility: Offers resistance to bending.

- Chemical Resistance: Has high resistance to many chemicals, such as acids and bases.

- Melting Point: Typically ranges between 130-171°C.

- Thermal Stability: Withstands high temperatures.

- Low Thermal Conductivity: Effective insulator against heat.

- UV radiation: Stable and weather-resistant against ultraviolet radiation.

You are familiar with the characteristics of polypropylene. Right? Perfect. Let's move next to the packaging for which this material is used.

Packaging Made From Polypropylene Material

The products made from polypropylene are listed below.

- Rigid Packaging: Containers and tubes that contain food like yogurt and ice cream are made.

- Bottles and Caps: Suitable for beverages. Good option to manufacture bottles and caps for cleaning products and personal care items.

- Caps and Closures: Produces secure sealing. Using secure caps for different types of bottles and containers makes it easy to close and open.

- Plastic Boxes: The boxes in different sizes are made to store items efficiently.

- Plastic Bags: To pack your snacks and other food products.

- Microwaveable Containers: Made from polypropylene, ensuring foods are safe from heat in the microwave oven.

- Medical Packaging: Syringes and other items related to healthcare are being produced.

Looking for a clear comparison! Keep reading!

Key Differences Between Polypropylene and Polyethylene

The primary differences between PE and PP are here. It can help you understand whether polyethylene or polypropylene is perfect.

| Features | Polypropylene | Polyethylene |

| Density | Lower than PE | Higher than PP |

| Chemical Structure | Consists of polymerized propylene monomers | Consists of polymerized ethylene monomers |

| Flexibility | Less flexible and more rigid | More flexible and less rigid |

| Melting Point | Higher (~160-170°C) | Lower (~115-135°C) |

| Resistance | Higher chemical and fatigue resistance | Better impact resistance |

| Transparency | Less transparent | It can be more transparent |

| Best For | Packaging, textiles, and automotive parts | Packaging, containers, and plastic bags |

| Cost | Most expensive | Cheaper |

Done with the comparison? Excellent. It's time to give final observations.

Concluding Thoughts: PP vs PE

The distinction between polyethylene and polypropylene is significant. The selection depends on your requirements. Polyethylene is known for its durability and low-temperature resistance. Cost efficiency is another edge. In comparison, polypropylene is heat-proof and chemical-resistant. Understanding the key differences between them can help you make the best fit.

Both PP and PE offer great strength and rigidity. To enquire more, feel free to contact Custom Product Packaging to discuss your requirements and learn which option is good to fulfill your packaging needs. Drop us a short message at our email orders@customproductpackaging.com.