PET vs PVC: Which Plastic Packaging Material is Perfect for You?

November 11, 2025

Choosing the right plastic packaging material can make or break the success of your business and product. In the growing plastic packaging industry, when its global market size is $413.89 billion in 2024 and is expected to reach $636.64 billion by 2034, two common types of plastic, PET and PVC, emerge as the big titans.

Wait. PET or PVC sounds similar. What’s the difference between them? Do they really differ from each other? Which one is better? These questions would be bulging in your mind. But worry not!

Read this blog to get insights into PET vs PVC and learn the key differences along with their applications, advantages, and disadvantages. Choose the right plastic packaging material according to your needs.

What is PET Plastic?

Polyethylene Terephthalate (PET) is a clear, strong, and lightweight plastic. It is used to create packaging for food and beverages. Further, it is a good choice for other applications such as clothing fibers and thermoforming.

The recyclability of PET plastic makes it safe for contact with food and beverages. Its food-safe properties ensure consumers enjoy beverages without worry.

Uses and Applications of PET

PET is used in vast applications for various industries, such as:

Textile:

- Woven and knitting belts

- Activewear

- Sportswear

- Jackets

Electronic and Electrical:

- Smart meters

- Capacitors

- Transformers

- Solar junction boxes

Packaging:

- Bottle and containers

- Fruit and vegetable trays

- Soap packaging boxes

- Cosmetic jars

Automotive:

- Connector housings

- Engine cover

- Wiper arms

- Gear housings

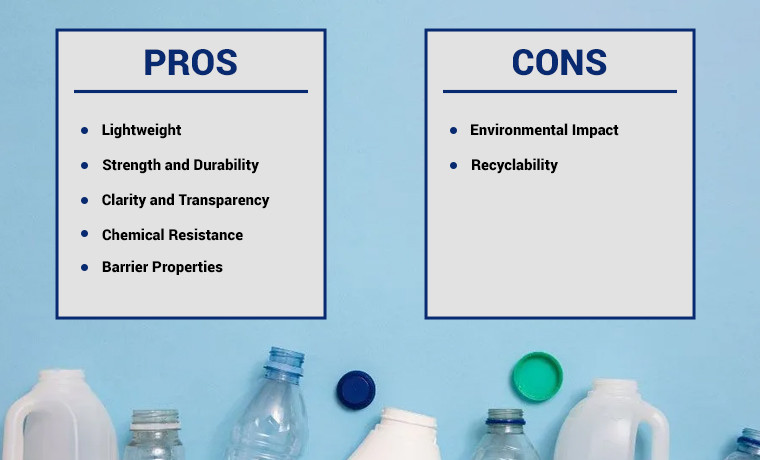

Pros and Cons of PET

PET is lightweight, durable, and recyclable. But if not disposed of properly, it adds to plastic pollution. A solution or a problem? That depends on how we use it.

Pros:

- Lightweight

Much lighter than glass or metal makes it easy to handle and carry.

- Strength and Durability

Incredibly durable and strong. It is less likely to break and offers extreme product safety.

-

Clarity and Transparency

Naturally clear and transparent, which allows customers to view the content inside.

- Chemical Resistance

More resistant to chemicals and highly effective in protecting the packaged products and maintaining the integrity of products.

- Barrier Properties

Offers excellent barrier properties against moisture, oxygen, and carbon dioxide, which helps extend the shelf life of products.

- Lower Heat Resistance

PET plastic is strong but less resistant to heat.

- Cost-effective

Inexpensive than other materials due to its durability and reduced production costs.

Cons:

Here are the disadvantages of PET plastic.

- Environmental Impact

PET is non-biodegradable. It can persist in the environment for longer if not properly disposed of.

- Recyclability

Not all PET-made products are recyclable. It faces recycling challenges and degrades over time as it is mixed with other materials that complicate the recycling process.

What is PVC Plastic?

Polyvinyl Chloride (PVC) - a type of plastic made from synthetic plastic polymer, is a strong thermoplastic material that can withstand harsh impacts and extreme temperature fluctuations. It is an economical option while offering excellent durability and chemical resistance.

Its characteristics make it popular in a wide range of applications, from cable and wire insulation to medical devices. This is not the end. It is also used to create pipes, faux leather clothing, hoses, roofing materials, and more.

Uses and Applications of PVC

PVC is used in vast applications for various industries, such as:

Medical:

- Blood bags

- Medical tubing

- IV bags

- Disposable gloves

Plumbing:

- PVC pipes and fittings

- Water supply lines

- PVC vent pipes

- Sewer lines

Automotive:

- PVC automotive components

- Floor mats

- Wiring insulation

- Headlamp lenses

Electronic and Electrical:

- Cable and wire insulation

- Switches and sockets

- Cable sheathing

- Battery casings

Pros and Cons of PVC Plastic

PVC is strong, versatile, and widely used in construction and packaging. However, it contains harmful chemicals and is hard to recycle. Useful or risky? That depends on how it's managed.

Pros:

Here are the benefits of PVC plastic.

- Strength

It is rigid and strong despite its lightweight nature. PVC plastic can easily handle pressure and weight in structural applications.

- Longevity

Highly durable and resistant to abrasion, which makes it perfect for creating pipes and flooring materials.

- Versatility

PVC plastic can be produced in rigid and flexible forms.

- Fire Resistance

PVC is naturally resistant to fire and does not catch fire quickly.

- Excellent Insulation Properties

The good insulation properties of PVC plastic make it a safe option for electrical cables and wires to reduce the risk of short circuits.

- Ease of Fabrication

PVC plastic is easy to cut and weld into different shapes.

Cons:

The disadvantages of PVC plastic are here.

- Toxicity and Health Concern

PVC plastic produces hydrogen chloride when burned. PVC melts when it is exposed to high temperatures. This can be a high health risk.

- Unacceptability by Municipal Authorities

PVC is unacceptable in consumer recycling programs by most municipal authorities in the USA.

Also Read: Matte vs. Gloss Lamination: Which Finish Is Right for Your Design

A Quick Comparison Between PET vs PVC

The table below shows the key differences between PET and PVC.

| Features | PET | PVC |

| Chemical Structure | Made from terephthalic acid and ethylene glycol | Made out of vinyl chloride |

| Strength | High strength and toughness | Flexible and rigid |

| Transparency | Highly transparent | Less transparent and not as clear as PET |

| Temperature Resistance | Good resistance to low and high temperatures | Lower resistance to high temperatures |

| Recyclability | Highly recyclable | Less recyclable than PET |

| Applications | Bottles, containers, food packaging, and clothing fibers | Pipes, cables, flooring, and medical equipment |

| Cost | More expensive | Less expensive |

PET Vs PVC: Which is More Recyclable?

Here is an overview to help you understand better which is more recyclable.

PET Recycling:

Known for its high recyclability. It is used for bottles and food boxes. Recycled PET (rPET) can be turned into new products.

PVC Recycling:

Less recyclable than PET as it releases harmful chemicals during the recycling process. This affects the quality of recycled material.

PET Vs PVC: What's The Perfect Match for Your Products

To understand which is even better for your packaging needs, here is a short overview.

PET Packaging:

- Transparent by nature and allows customers to view products inside.

- A lightweight but strong packaging material.

- Easy to transport and handle.

- PET plastic can be easily molded into various shapes and sizes.

- Highly recyclable and a considerable eco-friendly option.

PVC Packaging

- Durable packaging material to protect products from damage during shipping and handling.

- Can be made in different shapes and sizes.

- Ideal for a variety of products like pharmaceutical products.

- PVC window plastic for kraft paper window boxes gives clarity and allows customers to see what's inside.

Conclusion

After exploring each aspect of PET and PVC, from their applications to pros and cons, we conclude that these two types of plastics are essential in packaging. It totally depends upon the requirements to make the final decision on PVC or PET.

To understand their differences even better, consult with Custom Product Packaging's experts by dropping us a short mail at orders@customproductpackaging.com and select the right plastic for your specific needs.