What are The Different Folding Cartons Types

January 14, 2026

From the luxurious cosmetics packaging occupying store shelves to the cereal box you grab every morning, folding cartons are found everywhere. They are the foundation of contemporary product packaging in practically every industry since they are lightweight, highly adaptable, and customizable. However, most people are unaware of the variety of folding carton styles, structures, and crease patterns that exist.

Each has a unique engineering rationale, personality, and purpose. Selecting the correct style increases shelf presence, fortifies protection, and enriches consumer experience; selecting the incorrect style can result in shipping issues or a subpar impression.

Whether you're selling supplements, cosmetics, electronics, desserts, clothing, or handmade goods, this post explains the most common folding carton forms, specialty variations, functional lock bottoms, technical add-ons, and how companies should select the best design.

Understanding Folding Cartons

A folding carton is a pre-glued and flat-packed box made from duplex board, kraft stock, SBS (solid bleached sulphate), or specialty textured materials. It is printed and then cut to create a foldable style. Yes, it comes with pre-scored creases and is commonly referred to as :

- Cardboard folding boxes

- Small folding boxes

- Flat-packed boxes

- Paperboard Box with flaps

Folding cartons are used in many industries on many scales and regarded as the gold standard for retail-ready packaging. Why? They are lightweight, printable on all sides, and incredibly personalized. While robust frameworks guarantee sturdiness and presentation, their ability to stay flat-packed helps customers save money on transportation and storage.

It is used across industries:

- Food & Beverage

- Cosmetics

- Food and confectionery

- Toys, games, and stationery

- Pharmaceuticals

- Cannabis & CBD

- Electronics

- Retail Gifting, and more.

Popular Types of Folding Cartons Per Materials

Folding cartons come in two different types. Let's look at them and see why many brands rely on them.

1. Paperboard Folding Cartons

Paperboard folding cartons are lightweight boxes created from a single sheet of paperboard that is die-cut and folded into a three-dimensional presentation. Besides, these are commonly used for secondary packaging of retail products (food or cosmetics) and are shipped flat for cost-effective storage and transportation.

2. Corrugated Folding Cartons

Corrugated folding cartons are boxes made from two outer layers of corrugated cardboard with a rigid inner layer sandwiched between them. The inner wavy layer adds exceptional strength, making the boxes ideal to protect heavier or fragile items during shipping and storage.

Types of Folding Cartons Per Styles

For boutique packaging to high-volume retail, folding cartons come in a variety of shapes and structures. Each box differs from the others when it comes to closing type and user interaction. Understanding your options helps you find the ideal balance of design, function, and cost. Time to explore the most common styles.

1. Straight Tuck Box (ST)

Also known as Straight tuck end box (STE) or front-to-back closure, it is the common box type. The top and bottom flaps of the box tuck in from the same side, and slit locks to keep the bottom of the box closed. Considering this style needs no assembly before filling, STE is best for cosmetics, pharmaceuticals, and lightweight retail items.

2. Reverse Tuck Box (RT)

A reverse tuck box is a type of box with tuck flaps on opposite ends that open in opposite directions: one folds from front to back, and the other from back to front. This box design is very similar to STE, yet cost-effective and easy to assemble. It is ideal for lightweight retail products and high-volume runs of standardized products such as vape cartridges and bottled beverages.

3. Lock Bottom Box (LB)

Lock Bottom Boxes (LB) are commonly called 1-2-3 bottom boxes, which feature interlocking bottom flaps and multiple crease lines to create a sturdy self-locking base and secure closure. These boxes are the perfect choice for heavier or delicate items such as candles or glass jars.

Surprisingly, these are easy and fast to assemble because they involve only a simple "pop-up" mechanism. Interlocking flaps fold into place to form the support bottom.

4. Crash Bottom Box (CB)

Crash bottom boxes or auto lock bottom boxes are a type of packaging with an interlocking base that requires no tape or glue for assembly. These boxes are designed to "crash" open and automatically lock into place with pre-glued flaps. Moreover, it does not require additional folding steps at the bottom, making it suitable for carrying heavier items.

5. One-piece Tuck Top Boxes (TT)

This tuck top box is cut and scored from a single piece of material, featuring two top flaps that fold inwards and tuck into the box. This results in a secure closure. TT is surely a durable choice for items such as books, apparel, or electronics due to its simple yet effective design.

6. Two-Piece Boxes (TP)

A two-piece box consists of a separate base or tray and a lid that fits together snugly. This box is made from rigid material to provide excellent protection and offer a premium appearance to luxury items and gifts. The sturdy body ensures the product remains safe inside during transit and storage.

7. Holster Boxes (HOL)

Holster boxes refer to a retail packaging style where the top half of the box is open and has no closing tuck. Such packaging showcases your product in a simple way to grab customers' attention while encouraging direct interaction. These small foldable boxes are ideal for sample kits, travel sizes, or boutique items where compactness and visual appeal are crucial.

8. Sleeve Packaging (SE)

Sleeve packaging is a piece of paper or card that wraps around the product or its primary packaging. No ends or closing tucks!

It gives branding, product information, and an extra layer of protection without fully enclosing the item. The best part? Sleeves are incredibly easy to slide over the items and are best for testing newly launched colorful soaps or food products.

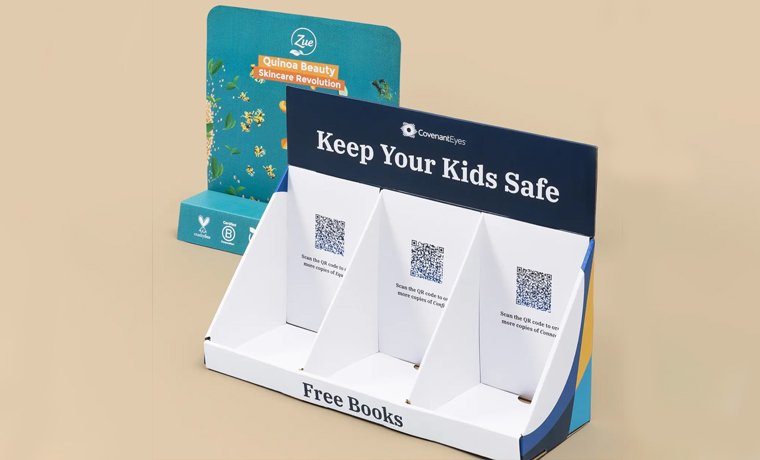

9. Counter Display Boxes

These flat tuck display boxes serve dual purposes. First, it acts as a packaging that protects the product. The lid unfolds into a vertical header when opened and instantly turns into a shelf-ready display. Second, it is a fascinating point-of-sale - showcase products and encourage impulse purchases. They are quickly and strategically placed to boost visibility and sales. Perfect for selling smaller items such as cosmetics, toys, and confectionery.

10. Five-panel Hanger Box

A five-panel hanger box features a built-in hanger tab at the top and a window in the middle, letting you display products on retail hooks. It offers a secure way to hang lightweight items, making it highly visible to customers. The creative design of this box offers a better branding opportunity and customization with logos, slogans, and colors.

11. Boxes with Inserts

This packaging features an insert or internal compartments - a piece of paperboard that holds and protects products securely. It prevents fragile products (glass bottles) from shifting, which can cause scratches, breaks, or other damage during shipping. These inserts keep items in place, making the packaging look more organized.

12. Folding Carton with Windows (Die-Cut Window Boxes)

Boxes with a window cut out in a unique shape and any size of your choice are best to let customers see the products before making a purchase. This cutout can be covered with plastic or not.

13. Boxes with Thumb Tabs

This is a small packaging box with a semi-circular cutout (thumb tab) on the lid or front flap. The thumb tab makes it easier to grip, open, and close the box without damaging it. These boxes are used for retail items like stationery, electronics accessories, and gifts.

Five Points to Help You Choose the Ideal Folding Carton

From structure to style, every choice matters. Consider these five key points to make the choice easier.

| Factors | Questions | Best Style Match |

| Product Weight | Is it heavy (>1 lb)? | Auto-Lock Bottom, 1-2-3 Snap Lock, Tuck Top |

| Assembly Method | Hand-filled or automated? |

Hand: Auto-Lock, Reverse Tuck Auto: Seal End, Flat Tuck Display |

| Retail Display | Will it sit on shelves? | Flat Tuck Display, Five-Panel Hanger, Simplex Tray |

| Brand Perception | Is it premium or budget? |

Premium: Simplex Tray, Infold Tray, Sleeve Budget: Reverse Tuck, Straight Tuck |

| Material Cost | Need to cut paper waste? | Reverse Tuck (best nesting), Sleeve (least material) |

Folding Carton Design Considerations

Design engineering is where folding carton magic starts. Here’s what packaging specialists evaluate:

- Die Line Planning: The way the carton creases, seals, and stands depends on your dieline. Precise dielines minimize printing aberration and assembling problems.

- Print Compatibility: Spot UV, foil stamping, soft-touch lamination, embossing/debossing, and matte or gloss lamination are all compatible with paperboard.

- Functional Add-ons: Hang tabs, tear strips, auto-close mechanisms, strengthened lock flaps, perforated panels, and more can improve practicality or aesthetics. Without completely revamping the packaging, these additions provide greater value.

Conclusion

Folding cartons are essentially collapsible cardboard boxes — shipped flat and stored efficiently. Your choice in folding carton types is an investment in your brand's perception, product safety, and customer satisfaction. By moving beyond a generic box with flaps to a strategically chosen style, you shape your packaging design with a simple cost into a silent salesperson.

Ready to design folding carton packaging that wows your customers and protects your product? Custom Product Packaging specializes in creating custom packaging that tells your brand story. Request an instant quote by contacting us via orders@customproductpackaging.com. Or call us at (+1) 888-511-0592.