What is the Gravure Printing and How is It Used?

November 21, 2025

Want to print millions of copies consistently and of high quality? What printing process best ensures consistent print quality on the whole run with minimum errors? You must be looking for a way. Worry not. You have landed the right piece of knowledge to get the solution.

The speedy and rapid printing solution comes as gravure printing to end this agony. It is a direct and ultimate printing process in which the image is etched on the cylinder for printing small and large run prints.

This blog will give insight into the gravure printing process with its types and applications, aligning its pros and cons to help you consider this printing method for your next project, especially for large-scale prints. Let’s get started!

What is Gravure Printing?

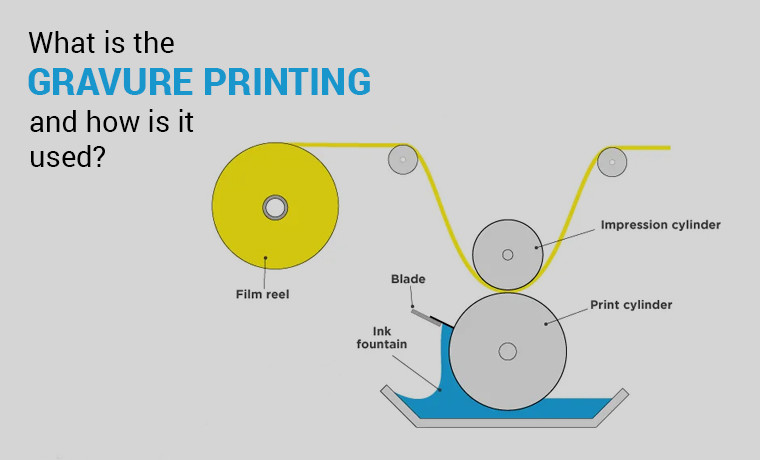

Gravure printing refers to rotogravure, which is an intaglio printing process in which engraved cylinders transfer ink onto a substrate. An image or design in this process is engraved or etched into a cylinder or plate. The engraved areas hold the ink, and the excess ink is wiped away.

This brilliant printing strategy helps produce precise and high-quality prints. This printing method is frequently used to print packaging for high-volume, long-run jobs, producing sharp details and rich colors.

This printing process is ideal for printing magazines and catalogs and promoting or marketing materials, especially when you need consistent quality and finely detailed prints.

Types of Gravure Printing

Most commonly, two types of gravure printing are used.

Engraved Gravure Printing:

A type of gravure printing is a high-speed printing process to transfer images on a substrate. Producing high-quality and consistent images makes this printing technique a good choice for various applications.

Process Of Engraved Gravure

The image is engraved onto a cylinder to create tiny cells that hold ink. The cylinder rotates in an ink fountain to fill the engraved cells with ink.

A doctor blade - a thin, flat tool scrapes off excessive ink from the cylinder surface and leaves ink only in the cells. Then, the cylinder presses against the substrate and transfers the ink from the cells to create the printed design image.

Applications:

- Magazines

- Catalogs

- Packaging

- Labels

- Wallpaper

Etched Gravure Printing:

In this type of gravure printing process, an image is etched onto the printing cylinder using a chemical etching technique. The etched grooves are then inked and pressed onto the material to produce high-quality and detailed prints. No mechanical or laser engraving is utilized to create images.

Process Of Etched Gravure:

Its process involves key steps, such as coating a copper cylinder with a light-sensitive material to transfer the digital image onto the cylinder. The cylinder absorbs a chemical that etches the image into the cylinder and prints the image on the desired substrate.

Applications:

- Magazines

- Catalogs

- Packaging

- Stamps and labels

- Banknotes

Applications of Gravure Printing

The gravure printing process produces high-end prints on a wide range of materials like paper and plastic. Offering efficiency and consistency, this technique is suitable for long print runs.

This printing method is ideal for printing securities such as stamps, certificates, and banknotes. However, due to the high cost, its use is less in general printing jobs.

Gravure Printing Examples:

The examples of gravure printing are here:

- Wallpaper

- Food packaging

- Wrapping paper

- Paneling

- Greeting cards

- Magazines

What is the Gravure Printing Process?

The following steps are for learning how gravure printing works.

- Pre-Press Image Preparation

Prepare your design images and make them ready to print.

- Plate Making and Cylinder Preparation

Create a gravure plate using the engraving method.

- Press Setup

Set up the printing press properly.

- Production Printing

Run the press to produce the final prints.

- Finishing

Finish the post-press processing such as cutting or folding the printed materials.

Also Read: The Supreme Guide To Understanding Collate Printing Technique

Pros and Cons of Gravure Printing

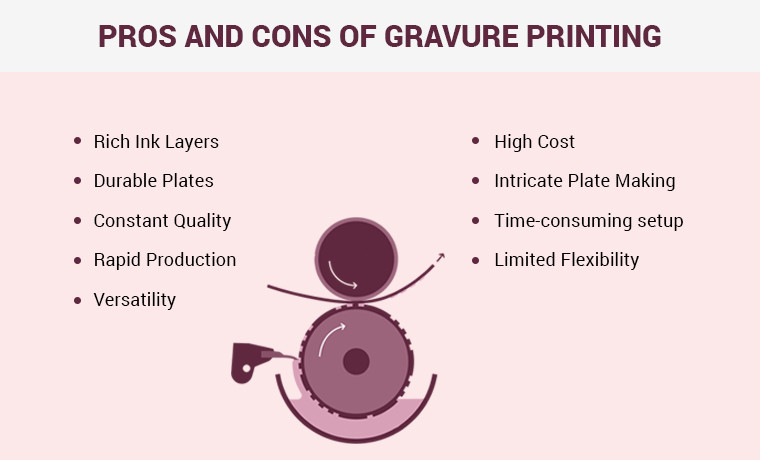

The perks and drawbacks of gravure printing are here.

Pros:

Below are the pros of using Gravure Printing:

- Rich Ink Layers

Gravure printing produces rich ink layers that result in vibrant colors.

- Durable Plates

Gravure printing plates or engraved cylinders are durable and ideal for large print runs without compromising quality.

- Constant Quality

Offers consistent and high-end results.

- Rapid Production

The fast Gravure printing presses process makes it ideal for large-scale printing.

- Versatility

Prints a vast range of materials from paper and plastic to metallic films.

Cons:

Below are the cons of using Gravure Printing.

- High Cost

Gravure printing is expensive for short print runs due to its plat-making process.

- Intricate Plate Making

Special skills and equipment are required in its complex plate-making process.

- Time-consuming setup

The lengthy process of creating and preparing gravure cylinders takes a longer time.

- Limited Flexibility

Unable to make changes to the image once a cylinder is engraved.

Other Gravure Printing Choices

Several other printing options emerge when you seek alternatives to conventional gravure printing. Offering flexibility and efficiency by combining their unique benefits and applications, the most common printing preferences are here:

- Flexographic Printing

Using flexible plates and rapid-drying inks, flexographic printing produces high-quality prints speedily. For printing packaging and labels, it is an excellent choice.

- Offset Printing

Offering accuracy and consistency with faster setup times, offset printing is perfect for producing medium to large-volume commercial print jobs such as newspapers, books, and magazines.

- Digital Printing

A modern printing technique using inkjet or laser printers eliminates the need for traditional printing plates. Providing faster turnaround time for personalized prints, this printing method is ideal for short print runs and on-demand prints.

Final Thoughts

Gravure printing is a speedy method to produce exclusive images using engraved cylinders to transfer ink onto surfaces like plastic. Producing vibrant colors and intricate details for long print runs in packaging, this type of intaglio printing is an excellent choice.

Need help to choose the right printing technique for your next project? Contact Custom Product Packaging by emailing us at orders@customproductpackaging.com to discuss this with our printing specialists and print your project the way you want.