What is UV Coating? A Comprehensive Guide 2026

January 01, 2026

The first impression is the last, right? The same thing is in the packaging industry. What’s the most effective coating technique you think is perfect to leave a lasting impact? How can your packaging stand out? Read on!

UV coating - an innovative liquid finishing technique has gained popularity and revolutionized the packaging industry. Don't know what is UV coating? No worries.

This blog will discuss UV coating by highlighting key features and looking into its types, applications, pros, and cons. Let's jump in!

What is UV Coating in Printing?

UV coating refers to ultraviolet coating. It is a clear liquid finish applied to printed materials and then cured with ultraviolet light to give a glossy surface effect. This finishing technique is ideal to provide a sophisticated look and enhance the overall finish of the material's surface.

Core Features of UV Coating

Here are the following key features of UV coating.

-

High Gloss Finish

Provides a shiny and polished look that enhances visual appeal.

-

Durability

Adds a protective layer to make the surface scratch-resistant and waterproof.

-

Quick Drying

Cure instantly under UV light and speed up the production time.

-

Chemical Resistance

Protects against stains and smudges.

-

Vibrant Colors

Enhances color brightness and sharpness for printed materials.

-

Customizable

Can be applied as a full coat for specific design elements.

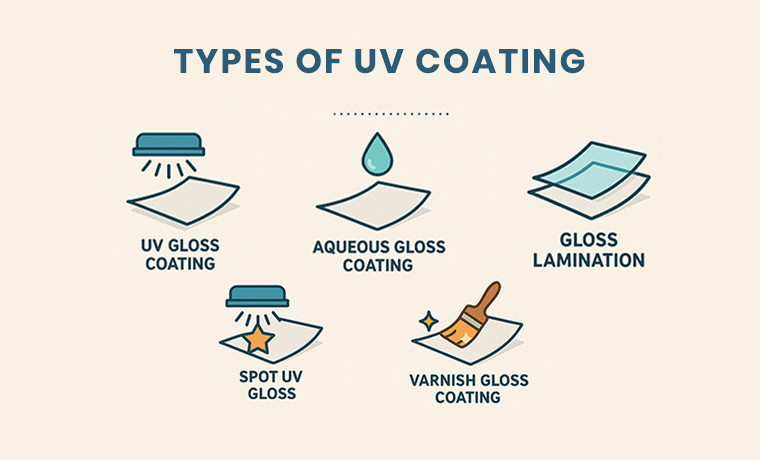

Types of UV Coating

UV coating comes in various forms and types.

-

Gloss UV Coating

Gloss UV coating is the super shiny and protective finish applied to printed materials. Think of this coating as a clear and glossy overcoat for your prints to make your message pop.

-

Matte UV Coating

Matte finishing offers a feel of elegance and luxury. It can be applied to specific areas to make colors appear richer.

-

Spot UV Coating

A finishing technique that is used in printing to add a glossy and raised effect to specific areas like the logo or text of the printed materials such as business cards and brochures.

-

Raised UV Coating

This printing method, also known as 3D or Sculpted UV coating, adds a raised and tactile effect to printed materials and creates a more engaging experience for users.

-

Orange Peel UV

Aligning a raised design with a textured finish that resembles the peel of an orange. This finishing type creates a unique tactile experience and visual effect when applied to the surface of the printed piece.

Applications of UV Coating

UV coating is a versatile and effective finishing process. It is used to enhance the appearance, durability, and functionality of packaging materials. Its applications are:

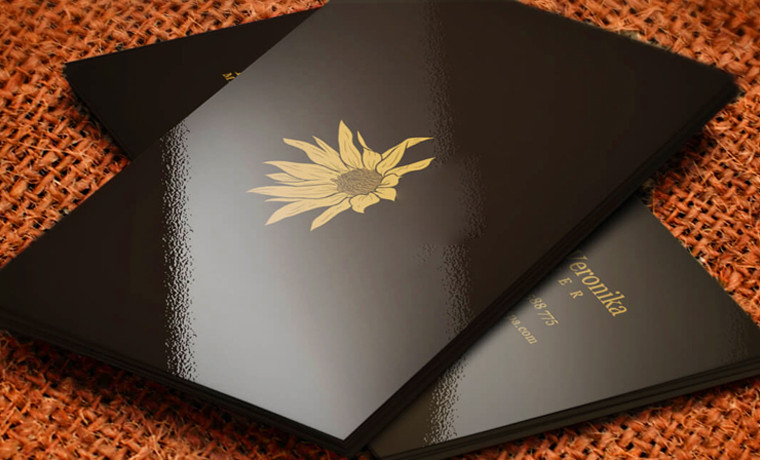

Business Cards

The UV coating on business cards makes them stand out and last longer when applied to their surface.

Luxury Packaging

High-end and premium packaging is known for its ability to enhance the visual appeal and durability of the packaging.

Marketing and Promotional Materials

The UV coating on promotional materials like brochures and flyers makes them visually appealing and durable.

Packaging

Ideal for packaging materials such as folding cartons and paper bags by adding a protective layer. This protects them from scuffs and moisture during handling and shipping.

Labels

The UV coating on labels provides a glossy finish to make colors pop. This enhances branding and design elements on labels that make them captivating on shelves. Moreover, it protects labels from scratches and moisture.

Food and Beverage Packaging

The UV coating, when applied to food boxes, provides a protective layer. This makes them moisture-proof and chemical-resistant. It can help to extend the shelf life of the product.

Cosmetics Packaging

UV coating adds a touch of glamour to perfume boxes and skincare product packaging.

Pros and Cons of UV Coating in Printing

UV coating has various advantages and disadvantages in printing. Let’s explore what they are.

Pros:

- Provides a high, shiny finish when used on deep colors like rich black.

- Offers resistance to abrasion and smudging while offering a premium quality appearance.

- Makes packaging details stand out on logos and photographs.

- Eco-friendly and recyclable.

- Dries quickly to minimize production time.

Cons:

- Not appropriate when using metallic inks.

- Unable to withstand extreme heat.

- Can be brittle and prone to chipping during transport.

- Less suitable for curved surfaces.

- May turn yellow with prolonged exposure to sunlight.

Key Factors to Consider When Selecting UV Coating

There are several core factors involved in getting your desired print outcome. These factors are:

Desired Level of Gloss Finish

Choose the right UV coating that can convey a true sense of compliment and a desired shiny finish.

Eco-friendly Impact

Consider a coating that has low volatile organic compounds (VOCs) and can minimize environmental impact.

Compatibility with Various Printing Technologies

UV coatings may be suitable with printing techniques like digital and flexography. Check out the compatibility of printing techniques for your next project.

Cost and Budget

Pricing is an important factor. Look into your project budget. Evaluate the cost with various types of UV coating. It can help you balance the cost.

Does Your Packaging Really Need UV Coating?

Your packaging truly needs UV coating for your projects. However, it depends on the type of product and your packaging goal.

UV coating is beneficial to achieve premium aesthetics, durability, and vibrancy. However, it will be costly and may not be suitable for all products. If you have a limited budget, you can skip eco-friendly and choose UV coating without sustainability.

How to Choose a Reliable UV Coating Supplier?

The following factors should be considered when choosing a trustworthy coating supplier.

Researching and Analyzing Credible Suppliers

Do a quick search to find the most reliable UV coating suppliers. Find out professional companies that have proven records of excellence. Glance at their reviews, customer experience, and the services they offer.

Evaluating Supplier Skills and Competence

Assess the capabilities and expertise of UV coating suppliers. Look into the details of those companies to ensure that they use specialized equipment, technology, and expertise to meet UV coating needs.

Quality Control Practices and Verified Certifications

Make inquiries about the supplier's quality control practices and certifications like ISO. Ensure they have a great quality control process to get high-quality UV coating results.

Pricing and Turnaround Durations

Pricing is another important factor. Compare different suppliers with their service and rates. Asses the UV coating quality, price, and delivery time they are offering to match your project needs.

Customer Support and Interaction

Assess the supplier’s customer support and responses. You must be sure how professional and fast they are to respond and serve their customers.

Conclusion

Now, you know UV coating and its types, along with their applications. We have also discussed advantages and disadvantages. It is clear that UV coating is a protective finish applied to printed materials. Offering a glossy appearance makes UV a good choice for various applications in printing.

If you have a question about UV coating for your next packaging project, contact Custom Product Packaging. Shoot us a quick email at orders@customproductpackaging.com.